The task is quite simple, but, at the same time, due to the large number of thermal pastes, it is no less time consuming than in the first part of the article - to find out which of the manufacturers of cooling systems equips their coolers with a really highly efficient thermal interface, and who - just thermal paste “to be ". Let's start with brief overview test participants.

Alpenföhn

The first thermal paste is taken from the Alpenföhn Nordwand cooler kit. The official website of the company has a "Scheekanone" thermal interface, but we will not undertake to claim that this particular thermal interface is supplied with Nordwand.The small syringe is completely devoid of any identification marks and is closed with a cap:

The color is white, the consistency is akin to thick sour cream, this thermal paste is applied and removed very easily:

AMA

Next in line is the included thermal paste coolers from AMA Precision Inc., about which the official website does not say anything at all, but on the syringe there is only the name of the manufacturer:

A viscous and plastic gray mass is easily applied and just as easily removed from surfaces:

Nothing is known about the characteristics of this thermal interface.

Cooler master

Cooler Master Thermal Grease comes bundled with budget Cooler Master or mid-range coolers such as Cooler Master Hyper 212 Plus or Hyper N620... A small syringe with a sticker with the Cooler Master logo contains 3-4 grams of a fairly thick light gray thermal paste:

Nothing is known about its characteristics, we can only add that this thermal interface is applied without difficulty:

Peeling off Cooler Master's thermal grease is also pretty straightforward.

Cooler Master ThermalFusion 400 (RG-TF4-TGU1-GP)

Cooler Master ThermalFusion 400 thermal grease comes with the flagship Cooler Master V10 cooler, but it is also a separate product... In our case, the thermal paste was tested exactly from the V10 kit:

The declared thermal conductivity of ThermalFusion 400 is 2.89 W / m K, which is quite modest by modern standards. The thermal interface does not leak, does not dry out, does not conduct electric current and has a very low thermal resistance.

Cooler Master ThermalFusion 400 is a medium thick thermal paste that is quite viscous and sticky. At the same time, it is applied and removed from the contact surfaces quite easily.

CoolIT

Thermal paste from CoolIT compact liquid cooling systems is sealed in a small 1.5 gram plastic bag:

Again, nothing is known about the characteristics of this thermal interface. The consistency is closer to liquid thermal pastes, but not fluid, the color is gray:

The prints on the GPU and cooler base are as follows:

Deep cool

Now let's get acquainted with the thermal interface from the set of the Deep Cool V4000 video cooler. In the previous article, we tested Deep Cool Z9 thermal paste, and the company's official website still has Z5 and Z3 thermal pastes. It is difficult to say which of them the Deep Cool coolers are bundled with, and this is not clearly indicated in the descriptions for the coolers.A small syringe contains only 2-3 grams of gray thermal interface:

Deep Cool Thermal Paste is quite thick, but despite this, it can still be applied in a thin and even layer:

There were also no difficulties with cleaning the surfaces from this thermal paste.

Ice hammer

Recently, Ice Hammer has begun to equip its cooling systems with a new highly efficient thermal interface. According to the manufacturer's assurances, the thermal conductivity of this thermal paste with a 25% content of silver particles is at least 7.5 W / m K, which is indicated directly on the syringe and for the complete thermal paste is an unprecedented case:

The consistency is thick, you can even say that Ice Hammer thermal paste is "dry":

At the same time, it is not much more difficult to apply it to the surface than most of the more liquid thermal pastes, and the layer turns out to be more or less thin and uniform:

Nexus

Next in line is the thermal paste from the Nexus cooler kit, in particular, the one that came with the Nexus VCT-9000 cooler. The official website of the company has a TMP-1000 thermal interface, however, as in the case of Deep Cool thermal paste, we are not inclined to assert that all Nexus coolers are equipped with this paste:

The little syringe turned out to be extremely informative. It contains information about the main characteristics of the thermal interface, including a rather high thermal conductivity of 6 W / m K:

The thermal paste is thick, but surprisingly plastic:

How Nexus, with such a thickness, managed to maintain plasticity and ensure ease of application is a mystery, but the fact remains: thermal paste is easily applied in a thin and even layer:

Removing Nexus from surfaces is very easy.

Prolimatech PK-1

Together with the Prolimatech Megahalems cooler and other cooling systems from this company, Prolimatech PK-1 thermal paste is supplied:

It is a viscous and plastic gray thermal interface with unknown characteristics, easy to apply and just as easy to remove from surfaces:

Scythe

Despite the presence in the assortment of the Japanese company Scythe Co, LTD. of such a good thermal interface as Scythe Thermal Elixer (SCYTE-1000), the company's coolers are still equipped with a small bag with an incomprehensible mixture. For example, the new Ninja 3 comes with the following package:

The thermal paste is very liquid, which is clearly visible not only by its spreading on the GPU, but also by the prints:

The characteristics of this thermal paste are not known.

SilMORE

Many budget air coolers are equipped with SilMORE thermal paste, which, however, has now become not white and semi-liquid, as before, but gray and thicker:

But the characteristics of the thermal paste have not changed - they were both secret and remained :)

It is easy to apply and remove thermal paste.

Thermalright Chill Factor and Chill Factor II

Two old Thermalright thermal pastes - The Chill Factor and Chill Factor II - are currently not listed on the official website among the products manufactured by the company (EOL). Nevertheless, in our opinion, it will be interesting to test them, comparing their effectiveness with the new Chill Factor III.

The first white thermal paste is similar in consistency to thick sour cream, but the second - already gray - is noticeably thicker, which can be clearly seen even from the photo:

Despite the difference in thickness of Thermalright thermal interfaces, both thermal pastes can be applied and removed from surfaces without much difficulty:

Chill FactorChill Factor II

Thermaltake

The package with the Thermaltake Frío cooler and many other coolers from this company comes with a small syringe with light gray thermal paste:

A viscous and plastic paste adheres well and adheres to the surface, forming a thin and uniform layer with sufficient pressure:

ThermoLab

ThermoLab Co., Ltd. also complements its cooling systems with high-performance thermal grease. In particular, the following syringe with a thermal interface is supplied with the new ThermoLab bada2010 cooler:

Unlike most other miniature syringes from cooler kits, ThermoLab does not skimp on the thermal interface - the syringe contains at least 5 grams of thermal paste, which is enough for 15-20 applications.

Thermal paste is plastic, viscous and sticky:

Can be easily applied in a thin and even layer:

Unfortunately, the characteristics of this thermal interface are not known.

Titan Nano Blue and Nano Grease

Two Titan thermal pastes - Nano Blue and Nano Grease - were previously also included in the kits of the cooling systems of the same name. It's hard to say how this is now. At least the latest Titan cooler we tested - Titan Fenrir - included Titan Royal Grease thermal paste, not one of these two:

Nano Blue stands out against the background of other products with a poisonous blue color and some dense blotches in the composition:

Nano Grease, in contrast, is a white and relatively liquid thermal paste:

Nothing is known about the characteristics of these thermal interfaces, and even if there were, there is no reason to believe them, as the first part of the article showed.

We add that Titan Nano Blue thermal paste was eliminated at the preliminary testing stage, completely refusing to carry out effective heat transfer between the GPU crystal and the cooler base:

Nevertheless, we award it the title of the best and, perhaps, the only thermal paste for modding!

Zalman ZM-TG2

Before the Korean company Zalman began to produce high-performance thermal paste Zalman ZM-STG2, all coolers of this company were equipped with a Lilliputian tube Zalman ZM-TG2, and later - the not entirely successful Zalman ZM-STG1:

Despite the small size of this tube, Zalman managed to place information on the composition (zinc oxide) and thermal conductivity (not less than 1.2 W / m K) on it.

The white thermal interface turned out to be quite thick (one might say - the thickest white thermal paste), but it can be applied and removed without any difficulties:

Zaward

Rarely seen on the market Zaward coolers are also equipped with a small syringe with white thermal paste:

The list of products manufactured by the company includes TCG002 thermal paste with a declared thermal conductivity of more than 6 W / m K, but no one knows whether it is in the syringe.

The declared thermal conductivity is more than 3.1 W / m K, the color is gray, the consistency is viscous and plastic: (formerly OOO Khimtek):

The 17-gram tube contains a medium-thick white thermal interface. The minimum declared thermal conductivity is from 0.65 W / m K, which, against the background of the thermal conductivity of other test participants, looks almost like a mockery. But there is a lot of it (KPT-8 thermal paste), and it costs only 30 rubles!

KPT-8 is non-toxic, non-conductive, non-flowing and non-corrosive. The operating temperature range is from minus 60 to plus 180 degrees Celsius. It is very easy to apply and wipe off surfaces:

It is not difficult to obtain a thin and even layer.

Well, here we have reviewed all 20 thermal interfaces that we found from the sets of processor and video coolers, as well as KPT-8. Let's check their effectiveness.

Test results and conclusions

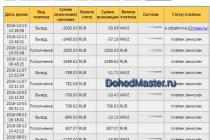

The testing methodology for thermal interfaces is completely identical. the technique used in the previous article... No indulgences were made to today's test participants. The duration of the running-in cycles was also maintained, and at least two test cycles of each thermal paste for each of the two applications were saved. Recall that the modder thermal paste Titan Nano Blue left the race in advance. The following new thermal pastes from the cooler kits discussed in the previous article have been added to all other test results for comparison: Zalman ZM-STG2, Thermalright Chill Factor III, as well as the mathematical leader of the first part of the article - Thermaltake TG-1.So which bundled thermal grease compares to the best thermal interface alternatives? So, the test results and conclusions:

In the leading group were thermal pastes such as AMA, Cooler Master ThermalFusion 400, Thermaltake (again), Thermalright Chill Factor II and ZEROTherm ZT-100. All of these five demonstrate the highest efficiency, comparable to the leaders in the face of Thermaltake TG-1 or Thermalright Chill Factor III (by the way, the latter turned out to be more effective than its related predecessor by only half a degree Celsius). It makes no sense to replace any of these thermal pastes with an alternative one, and the manufacturers themselves, completing their cooling systems with such highly efficient thermal interfaces, deserve respect.

Thermal pastes Prolimatech PK-1, Deep Cool, Nexus, CoolIT, ThermoLab and, surprisingly, gray SilMORE are kept within 2-3 degrees Celsius of the leading group. The predecessor of this thermal paste of the same name did not shine with efficiency, lagging behind the leaders by 7 degrees Celsius or more, but its replacement does its job. By and large, all six thermal pastes listed in this paragraph are quite effective, and if you are not chasing every megahertz when overclocking a processor or video card, then changing them to something more effective is hardly worth it. Indeed, as shown by previous testing, the difference between thermal pastes on the central processor will be even less than on the graphics processor.

Immediately after this group, four thermal pastes with insufficiently high efficiency can be distinguished, including Ice Hammer, Alpenföhn, Scythe and Thermalright The Chill Factor. And if the latter has long been discontinued and is not included in the package of new Thermalright coolers, then we would recommend such cooler manufacturers as Ice Hammer or Scythe to pay more attention to the thermal interfaces supplied with their cooling systems. They work, of course, but they don't work as efficiently as their competitors' thermal pastes.

Finally, among the frank outsiders, we immediately have five thermal pastes: Zaward, Cooler Master, Zalman ZM-TG2 and KPT-8. There are also small losses, since Zaward is a rare "bird", Zalman ZM-TG2 has already been replaced by the new Zalman ZM-STG2, and the Russian KPT-8 is not included in the cooling system kits and participates in today's test, one might say, out of competition. Except that a small Cooler Master syringe is often found in sets of coolers of the same name, but expensive models are already equipped with the new Cooler Master ThermalFusion 400, which we would like the company to include in all other Cooler Master coolers, including budget coolers.

This concludes the big thermal interface test. The choice, as always, is yours.

Due to the progress of modern microelectronics, the speed of central processors and other units of a modern computer is rapidly increasing. Often, an increase in computing power is accompanied by an increase in heat dissipation of a particular PC component.

It should be admitted that today semiconductor technology is faced with the problem of heat removal from crystals of the most powerful chips. So, the central processors and cores of top-end video cards are those representatives of the consumer microelectronic technology segment, where the heat dissipation per square centimeter is approaching 100 watts. For especially powerful chips, this indicator is further increased.

As it turned out, it is very difficult to remove heat from such a small area ... And so far it is impossible to drastically reduce the heat release of the mentioned components without resorting to very expensive research in the field of semiconductor and nanostructure technologies.

Of course, manufacturers are taking adequate measures - they have improved and continue to improve the cooling of certain computer components, promote water cooling to the masses, and develop new designs of air COs. A striking example of the expression of this movement in practice - the current "era of supercoolers", which literally swept the shelves and the minds of most users with masterpieces of technical art from copper, aluminum and heat pipes.

A high-quality cooling system is a guarantee of low temperatures of PC components, quiet operation, and the possibility of overclocking the system. However, in this case, it must be remembered that the "barrel of honey" can be easily spoiled with a "fly in the ointment".

Schematically, heat removal from a heating component (for example, a central processor) can be displayed as follows: "Processor - thermal interface - cooling system"(by the way, the heat-dissipating cover of a modern CPU contacts the core through another thin layer of the same thermal interface, but we will miss this point in this article, since the user cannot influence the characteristics of this factor). Most users forget about the binding component, which can be a tissue sticker soaked in various substances, a small sheet of foil, paste, ointment, liquid, or they use “what was in the box” - a free substance supplied with the purchased cooling system ... And many beginners do not even know about the existence of thermal interfaces and their use in modern computers!

Is this approach to seemingly trifles justified? Far from always, therefore, today's material is intended to demonstrate the importance of the topic under consideration and draw the attention of readers to one of the important aspects of cooling PC components - the influence of the thermal interfaces used on the quality of the heat sink.

Our goal is to research various substances that enthusiasts use in order to achieve the most efficient heat transfer from the processor crystal, graphics core, the motherboard chipset to the base of the cooler or water block. This provides an additional "margin of safety" during overclocking, or the overall temperature indicators of the components are simply reduced and the operating mode of a particular PC unit is facilitated.

Heat transfer: a little theory

For those who have forgotten or do not know what it is thermal interface, we will give the most understandable definition for the majority: this is the very layer consisting of some special substance that exists between the processor and the base of the air cooler or water block.

As you can imagine, the surfaces of the chip itself and its cooler are not ideal in terms of absolute evenness. In conditions of mass industrial production, it is often impossible to ensure a very high surface cleanliness and its geometric plane. Even on visually very even surfaces, there remain entire sections of microgeometry with imperfect contact, which, without the use of thermal interfaces, turn out to be filled with air molecules. These can be tiny indentations, bumps, or micro-scratches that are invisible to the naked eye.

Heat transfer to honey by contacting surfaces is carried out by means of conduction... This term denotes the process of exchange of kinetic energy between molecules of substances together with the diffusion of electrons in metals. Heat transfer by conduction will take place under the condition of contact of bodies with a temperature difference. In all cases, the heat flux will be directed towards the fall of the gradient absolute values... Consequently, the bulk of the heat energy goes from the chip to its cooler.

Convection and radiation separately are not able to remove huge heat fluxes on a small area of the microchip, and only partially take part in the general heat exchange.

If we touch on theoretical physics a little, then it should be remembered that thermal conductivity of metals determined by the vibrations of the crystal lattice and the movement of free electrons (the so-called "electron gas").

With increasing temperatures, all metals have electrical conductivity, and, as a result, thermal conductivity decreases (these two phenomena are interrelated and one does not occur without the other). On the contrary, with decreasing temperatures, thermal conductivity increases.

The presence of free electrons determines the high electrical conductivity of metals.

Knowing this, it becomes clear why aluminum, copper, silver and their alloys are widely used in the manufacture of parts for cooling devices. These common metals have the highest electrical and thermal conductivity of all known to the mainstream industry. In addition, it is relatively easy for them to give the desired shape through appropriate processing. We give brief characteristics thermal conductivity of the most available metals and some interesting materials that are used in certain industries:

But back to our "rams": we have two surfaces - the chip crystal and the base of the cooling system, which is tasked with cooling it. The thermal interface displaces air, and forms a film between them, consisting of a substance with a low thermal resistance.

Various pastes also allow mechanical decoupling of the heat source and its cooler, which is necessary in case of replacement of any PC component.

If fasteners for radiators are not provided, or if a more rigid fixation of heat sink devices is required, then hot-melt adhesives and special stickers are used. In this article, these types of interfaces are not considered, however, based on the data given in one of our earlier ones, it is possible to roughly estimate the effectiveness and other characteristics of some products of a similar plan.

We hope the readers have no questions left on the theoretical side, so we will move on.

Test method

When choosing a reference paste, we proceeded from the following considerations:

- mass availability of the test sample;

- high efficiency;

- ease of application and rinsing;

- low cost.

We think you have already guessed that we are talking about a rather old masterpiece of the domestic chemical industry - pasta. KPT-8... The key to total popularity for a huge number of users is the excellent price / quality ratio of this product.

But not everyone is satisfied with the parameters of the specified paste. Among those who use PC intensively, there are so-called "racers", enthusiasts. They crave fame and records, force the modes of operation of iron by everyone available ways, thereby squeezing megahertz, parrot-strength, and, as a result, creating more difficult working conditions for various PC components, invariably leading to increased heat generation. It is clear that in a state of record performance, the system will be very unstable. In this case, every degree and every extra watt of dissipated heat will be decisive.

In such conditions, increased requirements are imposed on any component and link of the cooling system, and sometimes even exceptional ones are imposed on the thermal interface, because nothing will worsen the heat dissipation like low-quality thermal paste.

As we have already said, the powerful microprocessors of modern PCs are perhaps the only segment of consumer microelectronic technology, where the heat dissipation of the crystal often reaches more than 100 watts per square centimeter. As it turned out, it is very difficult to remove heat from such a small area, so many companies are engaged in the research and development of devices and substances designed to efficiently remove heat from central processors and video card cores.

Within the framework of one good test on a PC, everything seems extremely clear and understandable. However, when looking at and comparing a significant number of reviews and articles published on the web, we sometimes found conflicting research data and ambiguous conclusions drawn by their authors.

In almost all cases, direct or indirect emphasis was placed on the processor on which the tests were carried out and the cooling system used.

This prompted the Test Laboratory site to collect all the thermal pastes available to us and conduct our own independent investigation using a special test bench.

After reviewing the results of the study of the characteristics of thermal pastes, carried out on the CPU, you can see that in the overwhelming majority of cases it is difficult to feel the difference between samples with similar characteristics. Much depends on the architecture and TDP of the processor. With an increase in the heat release of the heater, the difference between the investigated thermal pastes becomes more and more obvious.

We noticed another interesting point. So, manufacturers indicate the thermal conductivity of pastes on the packaging of their products, but it is not enough to determine the winner by this indicator.

The reason is simple - different methods of measuring thermal conductivity give different values. Even conducting research according to a single method in several laboratories does not exclude obtaining inaccuracies in the final results. For example, a paste may have a different contact layer during the test, and this will directly affect the digital expression of the subjective results of the study.

Undoubtedly, only empirically by means of a single _large_ comparison according to a single method you can find actual differences between the test takers.

We chose the proven MARK Sea Launch experimental test bench as a stable heat source.

On this modification, the heater core has an adapter with a small area (less than 12x12 mm), which makes it difficult to transfer heat from the heat source to the lid. The upper, polished part of the heater "emulates" the processor's heat spreader. Its dimensions are 25 x 25 mm, thickness is 2 mm.

With a power dissipation close to 100 watts, the heater looks like a powerful overclocked processor, which would be very difficult to cool in real conditions. The microprocessor-based thermal sensor embedded in the core of the heater is capable of registering temperature changes in tenths of a degree.

The heater power was set at 100 W. This value fit perfectly. It's nice that the final temperatures turned out to be about the same as on modern processors with average COs.

Accordingly, our powerful heat source will require at least a powerful cooler, and it is possible that a liquid one. But it is difficult to test thermal pastes on a water cooling system. It is possible to introduce an error in the test due to the presence of an intermediate heat carrier (water) acting as a condenser between tests. This means that the system will have a certain inertia. Such moments are always an inconvenient bottleneck for lengthy and laborious research.

When testing air coolers, the test results are more stable, which is confirmed by testing control samples at long intervals.

The heart of our cooling system is the Noctua radiator, model NH-U12. This sample is assembled on four U-shaped heat pipes that are in contact with a copper base, and solid aluminum plates. We decided to overclock it a little, and equipped the radiator with two 120 mm Sunon KD1212-PMS1 industrial fans with a capacity of 181 cubic meters / hour each.

This configuration made it possible to achieve a record productivity of the air cooling system, significantly exceeding the power of budgetary air cooling kits.

The cooler was clamped with a pair of screws through the standard mounting holes socket 939... During the tests, there were no shock-absorbing springs, the clamping force was not regulated. In each test, the screws were tightened to the limit, which guaranteed the formation of a thinner intermediate layer of thermal paste and, as a result, the most correct final result.

In the room in which the testing was carried out, the air temperature was at the level of 27.5 ° С, monitoring was carried out continuously. In case of exceeding the threshold of this value by 1 ° C (in any direction), the stand automatically issued a warning signal, and the study was suspended.

Whenever possible, each paste was tested at least twice. In this case, the contact layer was applied anew, and the result obtained will be refined.

For pastes that showed unexpected, suspicious results, or that took some time to fully return to optimum condition, the test was repeated after a few days. *

.

Please pay attention to charts- they are deliberately built "incorrectly" to more clearly demonstrate the difference between the tested interfaces. So, the starting point is taken at 45 ° C, so do not be alarmed by the relatively large visual difference between some substances on the graphs showing the final results.

* during the entire time of research, the room was kept at the same temperature

Thermal paste parameters

Regardless of the model and name of the manufacturer, any sample of good pastes must meet the following requirements:

1) the lowest thermal resistance;

2) stability of properties in a fairly wide range of operating temperatures;

3) ease of application and ease of washing off;

4) the invariability of properties over time.

We believe that it is necessary to dwell on each of them in more detail.

Lowest thermal resistance the applied layer will ultimately determine the ultimate thermal conductivity of the paste for a given contact area. If the values of operating temperatures are within reasonable limits and the substance does not lose or change its properties during the entire period of operation, then the parameter of thermal conductivity will be the only and decisive one.

Working temperature range

All high-quality thermal pastes work great in a home computer at standard temperatures. Recall that in PC in most cases we are dealing with values of the order of 30-80 ° C at the point of contact.

The comparison will be made within this "positive" range.

Temperatures above 100 ° C, for obvious reasons, are not considered in principle. Also, anything below zero down to -200 ° С is already extreme, which is the topic of another conversation. How different pastes will behave in this case, we do not know, and we will not put experiments in this direction today.

Ease of application is a very important factor, and if the paste is applied with great difficulty in a thin layer to the contact surfaces, or it is very poorly washed off, contaminating everything around, then this gives certain problems to the user and definitely reduces the overall score, even despite other high parameters.

Stability of properties over a wide time range determines the "vitality" of the paste. For example, we know a lot of cases of drying or partial drying of low-quality samples of KPT-8 during its operation, even for one month! Naturally, the thermal interface, which demonstrates similar indicators for a given parameter, can at best be used only for short tests.

Such characteristics as dielectric strength and dielectric constant, specific volumetric electrical resistance and other special indicators for any PC user are for the most part irrelevant.

In the process of getting acquainted with thermal pastes, we will not dwell on the description of the physicochemical properties, as others do, but focus only on the main criteria for us.

Acquaintance with thermal interfaces: general impressions

KPT-8

First, we will smear our reference paste, which we successfully use in all tests. You probably already guessed that we are talking about the domestic KPT-8. One of the G8 samples was purchased at the Kiev radio market. The filling of a 10-cc syringe usually lasts a long time, but we always use a reserve of paste. The true manufacturer of the paste is unknown, there are no identification marks.

In ordinary syringes, the paste is filled from large capacity, and clearly not far from the place of their subsequent sale.

This sample of KPT-8 is squeezed out with some effort, but with frequent use, you can quickly get used to it.

In appearance, the paste is white, does not contain any inclusions, rather thick.

After application, for correct testing, the paste must be spread over the surface with a thin layer. A spent card for city payphones, or a clean finger of the user, is well suited for these purposes :)

Usually manufacturers declare thermal conductivity of this type pastes in the range of 0.5-0.8 W / (m x K) (hereinafter, in the characteristic of the unit of thermal conductivity, degrees Celsius are replaced by the more common unit - Kelvin). It is she who in all comparative tests on the diagrams will be present under the designation "Etalon".

The tests also contain KPT-8, but this time from a smaller syringe, on which a red sticker flaunts with the image of Mendeleev and the name of the contents (popularly nicknamed "Mendeleevskaya").

Like the first sample, it is very common, but purchased elsewhere on the radio market :).

It is applied and smeared somewhat better than the previous one, and not so thick. It looks no different from our standard.

The next sample is also a "figure eight", with the same "hacky" sticker. But now it is already called KTP-8 - this is something new! I wonder if they are somehow different? (looking ahead, let's say that nothing). Obviously, there was a problem with the name of the sellers-packers :).

Oh my God, the next tester is also CBT-8! But this time the pasta is really special. The originality lies in the use of beryllium oxide in its manufacture, BeO... This sample has recently been actively promoted in some points of sale. True, its price and "packaging" are no different from "Mendeleevskaya".

It's funny, but there are legends on the Internet about the use of beryllium oxide (BeO) as a heat conductor. There are rumors that this is a rare paste of the military space intended purpose with amazing characteristics.

In our case, vague pictures from the fantastic film "Shadow", a beryllium sphere, an ancient evil, and so on appear before our eyes;).

Whatever it was, but in the specified GOST 19-783-74 nothing is said about beryllium oxide, in fact, it is not said about the exact composition of the paste.

For those who do not know, we recall that in the traditional KPT-8 finely dispersed zinc oxide is the heat conductor. What about beryllium?

The information raised in the analytical chemistry of this metal suggests that, indeed, beryllium oxide combines high thermal conductivity and low electrical conductivity. It is used in special ceramics and in many branches of science and technology. It is quite possible that thermal paste can also be produced on the basis of BeO.

By the way, beryllium compounds are definitely poisonous, but the degree of this indicator depends on the specific compound. No reliable information has been revealed about the toxicity of the oxide, as well as the very fact of the presence of BeO in the paste under consideration.

To establish the truth, it is necessary to conduct a chemical analysis of the paste, and this is already a certain problem for any test laboratory, even a large one. and x Internet resources. Therefore, we will limit ourselves only to the test.

AlSil-3

Thermal paste, which is very popular among domestic users. Produced by the Moscow firm GM Inform. There are a lot of rumors about the substance in question on the Internet. Apparently, one of the reasons for this is its maximum declared thermal conductivity, which is approximately 2 W / (m x K), having forgiven 0.8 for KPT-8. On the forums, some users report excellent results with the use of AlSil-3, unlike other domestic rivals, while others do not feel any difference, or, on the contrary, more approve of the G8. They claim that there are fakes AlSil-3 based on toothpaste *

... There are also assumptions that the manufacturer is experimenting / saving, and does not always guarantee consistently high performance of the products.

*

for interest, we also tested toothpaste to find out if it is possible to make a fake in this way; see the research data at the end of the article

For tests, we got two samples of the substance in question - the original, branded AlSil-3, released in the second quarter of 2006:

And one more syringe of a slightly larger size with the AlSil-3 marking:

A visual comparison showed that the pastes from both syringes were no different. The substance in each case has a characteristic gray tint. This feature of AlSil-3 is dictated by the presence of aluminum nitride in it, which acts as a heat conductor. There are no inclusions in the composition. The paste is squeezed out simply and spreads easily. Of our two samples, AlSil-3 in a larger syringe was released quite a long time ago, approximately in 2002. However, during testing, no difference was found between the pastes.

This thermal interface is supplied with akasa coolers.

The paste is in a small syringe, has a white color, compared to our standard, it is more liquid and easier to smudge.

The thermal conductivity coefficient declared by the manufacturer is more than 7.5 W / (mx K). In theory, this is about 7 times more than that of KPT-8! And what will happen in practice? ... Testing will show!

AOS is a very well-known manufacturer of thermal interfaces abroad.

For testing we got silicone paste, # 54013, packed in a branded syringe.

Has a white color, easy to apply. Washed off without any problems. The consistency is very liquid.

The declared thermal conductivity of this sample is 0.73 W / (mx K).

Apus – TMG 301

We got this sample from the XC-801 cooler kit from LEXCOOL.

The paste has a slight grayish tint and resembles AlSil-3.

The consistency is rather liquid. The indicated thermal conductivity is of the order of 4.5 W / (mx K).

Arctic Cooling MX-1

This paste is one of the unconventional products of the Swiss company Arctic Cooling, which specializes in the production of quiet and high-quality cooling systems. We are already about this product, so we will not dwell on the details.

The substance is in a proprietary syringe, which, by the way, changed its appearance... Ash-colored paste. Squeezed out in small lumps. For proper application, it must be rubbed into the base of the cooling system and the processor cover. Note that on both surfaces you need to apply very little paste, remove the excess.

This is the "old" packaging option:

And here is the paste in a new package in a thinner and longer syringe:

Arctic alumina

This paste is the brainchild of perhaps the most famous and advertised foreign manufacturer of thermal interfaces - Arctic Silver.

Arctic Alumina is made from aluminum oxide. The paste is white, it is easily applied to the surface, it is just as easy to smear. The declared thermal conductivity is over 4.0 W / (mx K).

Arctic ceramique

The heat conductor in the paste is a mixture of aluminum oxide, zinc oxide and boron nitride; the manufacturer does not indicate the proportion of substances.

Arctic Ceramique, like all Arctic Silver products we test, is made on the basis of a proprietary highly stable polysynthetic base. There were no problems with application and rinsing of the product.

Arctic Silver 3

One of the most famous silver-based pastes. The composition is a dark gray substance with a greenish tint.

The manufacturer indicates the content of approximately 70% fine silver by volume of the paste.

The substance is squeezed out and applied without problems, it is removed quickly and easily.

Antec reference

Looking at the syringe, it is easy to guess where and by whom the paste was produced.

Interestingly, the package claims to reduce the processor temperature by 4 ° C to 15 ° C due to the use of this thermal paste. We could not understand in what case it is possible to achieve such outstanding performance ... Perhaps the marketing specialists of the manufacturing company mean the difference between installing a cooler without using any thermal interface, and using Antec Reference :)

The product in question has exactly the same characteristics as the Arctic Silver 3, and the tests carried out confirm this.

Arctic Silver 5

This product replaces Arctic Silver 3 and has improved performance. This time, the presence of 88% of finely dispersed silver of high purity in the paste is indicated.

The substance is dark gray in color, with a rather thick consistency. To spread the paste in a perfect thin layer, you need to spend certain time.

The declared thermal conductivity of this product is impressive - about 8.7 W / (mx K).

Many well-known companies use Arctic Silver products under their own brand, often with their own packaging. For example, Arctic Silver 5 is referred to as Thermal Grease # 2 by Thermaltake.

This thermal paste comes with the Asetek WaterChill KT03A water cooling system.

The substance is contained in a dense white sachet, which is enough for several uses.

The paste is white, in places liquid, but mostly in small lumps. Smears normally, rinses off easily.

Data Сooler

This thermal interface is supplied in bags with coolers produced under the same brand name.

The pasta is very similar to the Polish W.P. - much more liquid than KPT-8. There were no problems with the application.

Standard "silicone" thermal grease.

Abroad DC-340 is found in many chemical manufacturers. Our paste is in a plastic tube. When squeezed out, it turns out that it is very thick, stretches, and has a white color. Typical thermal conductivity DC-340 - 0.42 W / (mx K).

Fanner 420

This thermal paste is also known as Evercool 420, but in fact we have a product from Stars with the same digital designation - 420. As you can see, this thermal interface is very popular among many suppliers.

White paste, very liquid. The indicated thermal conductivity is 2.062 W / (mx K).

GeIL GL-TCP1b

Quite an interesting example. Recall that Geil manufactures random access memory. A tube of thermal paste could once be purchased separately, or found bundled with some modules as a free customer bonus.

The composition is very beautiful, so to speak, golden in color. The manufacturer indicates the presence of 5% copper and 5% silver (by volume) in it.

I wonder what thermal conductivity this "mix" has? On the syringe label, you can find a value of 1.729 W / (m x K), which most likely looks like the truth. However, the real effectiveness of GeIL GL-TCP1b will be determined by testing.

The composition of this paste is liquid, homogeneous, applied in layers, spreads easily. This substance is removed a little easier than the ever-memorable "silver".

Gigabyte

We fished out this paste from the Gigabyte 3DGalaxy SVO kit.

Note that the manufacturer gives a far from full syringe, and the substance is enough for only one or two water block installations per processor.

The paste is white, very liquid.

Koolance

We got this sample from the CBO Koolance Exos kit. Actually in front of us - Stars 360, keep this in mind.

Ash-colored paste. Thick, but spreads relatively easily. Quite high thermal conductivity is declared - about 4.5 W / (mx K).

This product is included in the Noctua cooler package. The paste is in a small syringe filled to capacity.

The substance is white, unremarkable, liquid and slippery.

Pasta Siliconowa

This paste is quite common on the market. Manufactured in Poland. We hope you understand that in "silicone" pastes, the heat conductor is not the substance that is used to increase certain parts of the female body, but mainly metal oxides :).

The paste is contained in a tin tube. White colour; thick, like our reference, but easy to apply and smear.

Note that it is extremely inconvenient to squeeze the paste out of such a tube.

The next thermal paste is also Polish, packed in disposable sachets. There are no identification marks, but the seller managed to find out the abbreviation of this substance - W.P.

The paste is very liquid, it is applied very well, in a thin layer.

Panasonic

Do not be surprised that the well-known company Matsushita Electric Co. (owner of the Panasonic trademark), among other things, produces thermal pastes for use in its own production.

The product for retail sale is packaged in a small round jar with a red lid.

The pasta itself turned out to be like whipped cream, "airy". As soon as the cooler is installed on the processor, it will instantly squeeze out the excess amount of substance outward, so in this case you can not worry about a thin working layer.

Possibly a Stars product. Many manufacturers use thermal pastes from this vendor, often "re-releasing" them under their own brand.

The thermal conductivity of the composition indicated on the syringe is 0.88 W / (mx K), which is very similar to the characteristics of our standard. The paste is white, very thin and easy to smudge.

Shin-Etsu

We cannot name the exact model of this substance, but buying it will not be a big problem. In some cases, the user may receive a package that will be provided with a sticker. According to the sellers, these syringes are filled with thermal paste from Shin-Etsu MicroSi, Inc.

It was not possible to find out the nominal characteristics of the product. The paste is white, very similar to the "Mendeleevskaya" KPT-8. It is applied normally, a little "slippery".

Stars (soft pack)

Another product made by Stars. Perhaps it is no different from other similar substances.

In appearance, the paste is white, somewhat slippery, with a consistency reminiscent of the substance from the Data Cooler set.

Stars silver

And this is a non-standard thermal paste from Stars, very similar to the Titan TTG-S104. The substance is well applied and smudges on the surface of the processor heatsink cover.

True, during washing off, the same problems arise as with the "silver".

Stars 700

Like other relatives from this manufacturer, it is also a very common pattern. Interestingly, the manufacturer indicates the presence of 25% silver by volume in the composition of the paste. Unfortunately, we will not be able to verify this statement within the framework of today's test.

The indicated thermal conductivity is 7.5 W / (mx K). Composition of silvery color, lay down in layers. It is very reminiscent of the "titanic silver".

Aero 700

Aerocool cooler paste.

In fact, we have Stars 700 in front of us, but in a different package: the same 25% silver by volume and a thermal conductivity of 7.5 W / (mx K).

Sil more

The paste comes in a transparent plastic bag. It looks white, very liquid.

When squeezed out on the processor cover, in addition to the paste, some other transparent substance appears. This thermal interface is easily applied, it is easy to wash off.

Shin-Etsu MicroSi G-751

On the syringe, except for the identification mark in the form of the manufacturer's name, there was nothing else, but we managed to find out the true name of the product - G-751.

The paste was included with one of the coolers for server processors Intel Xeon... The composition is gray in color, rather thick, is in a thin and long syringe. The thermal conductivity declared by the manufacturer is 4.5 W / (mx K).

Shin-Etsu MicroSi MPU-3.7

This sample of thermal paste has been preserved since the era of AMD Athlon XP (K7) processors!

I wonder what result this substance will demonstrate. The paste itself is dark gray, very thick.

MPU-3.7 is not spread in the best way, if I may say so. Like Arctic Cooling MX-1, it must be rubbed into the surface in a thin layer for normal application.

Titan TTG-S104, -S103 (silver)

This substance was previously supplied in a small sachet or syringe with Titan coolers. Here it is one of the most famous and widespread thermal pastes. For its specific color and composition received the nickname "silver".

The paste is really silver in color, but nothing more: it seems to us that silver is absent in the composition by definition, although the manufacturer claims some percentage. It seems that finely dispersed aluminum powder is the heat conductor.

The paste is squeezed out easily, lays down on the surface in layers, spreads well. The filling in the syringe is more convenient, so when choosing between S104 and S103 do not get lost - there is no difference between them, except in the packaging, we have one and the same substance in front of us. The peculiarity of "silver" appears at the moment this interface is washed off - the composition quickly, as if expediently and spontaneously, appears on some parts of your body, and on objects that have undergone the slightest contact with the paste or the user's soiled hands.

We have probably never met such a "dirty" thermal interface.

Titan nano blue

One of the options for replacing the classic "silver". In the form of a small syringe, it is included in the kit of coolers and water cooling systems from Titan. It is a very common model, but tests will show how successful it is.

The composition of the syringe itself is of a radical blue color, lays down in layers, is not smeared in the best way. Nominal thermal conductivity - more than 2.5 W / (mx K).

Titan Nano Grease TTG-G30010

This thermal interface is the newest product of its kind from Titan. Apparently, it will replace the well-known Nano Blue paste.

The tested product comes in a small flattened syringe that comes with new coolers from the manufacturer in question.

The composition is gray. The paste is very thick, viscous and dense, so it will take some time to evenly apply. The declared thermal conductivity is 4.5 W / (mx K).

It is worth noting that the same thermal grease is available separately in retail:

The only difference from the sample we tested is the delivery in a syringe of a noticeably larger volume and, as a result, labeling TTG-G30030.

Thermopox

Before us are the products of the well-known company Amepox in certain circles.

The substance in question is taken from a two-component set designed for gluing heat sinks to cases of memory chips and / or power transistors. The heat conductor is a rather original mixture based on liquid finely dispersed copper.

The indicated thermal conductivity of the composition is 6.4 - 6.8 W / (m x K).

Zalman CSL 850

A very common pattern. This paste is included in the kit of the overwhelming majority of coolers manufactured by Zalman, which determines its mass availability and wide popularity.

The composition is in a miniature tin tube, which is enough for two or three uses. White paste, relatively liquid, easy to apply. The declared thermal conductivity is 0.837 W / (mx K). Many people constantly use CSL 850 and speak about its good properties, better than those of KPT-8. Nevertheless, these thermal pastes are very similar, and, most likely, their effectiveness is approximately at the same level. Whether it is true or not, testing will show.

47 D90T8-010 GFC-M1

Before us is a dark ash-colored paste. It was not possible to determine any identification marks, except for marking, and the origin of the substance.

The product in question was part of one of the laptop self-assembly kits. But since she turned up under the arm - why not test it ?!

Coollaboratory Liquid Pro

This substance is the first serial thermal interface based on liquid metal. Those who had an interesting childhood probably beat thermometers behind garages and rolled balls of mercury. So, this composition evokes nostalgia for old ideas and experiments with liquid metals. The substance has a characteristic lustrous metallic color.

This alloy does not evaporate, is not as toxic as mercury, and does not form such hazardous compounds. This thermal interface consists of rare earth metals, alloyed in a certain proportion. Its melting point is below room temperature. But that doesn't mean you can do whatever you want with Liquid Pro. Like mercury, this metal reacts chemically with many other metals. So, after a while, oxide flakes grow on aluminum parts, and they themselves literally decompose and dissolve at the point of contact (this behavior is typical for gallium). In this case, transmetallic compounds are formed. On copper, this process will also occur, but not so quickly and far from so clearly.

Unfortunately, Liquid Pro is also difficult to apply.

All attempts to smear liquid metal will be in vain if several conditions are not met to ensure the proper effect. The contacting surfaces of the chip and the cooler must be clean and smooth, copper must be free of oxides. It is best to pre-treat the sole of the cooling device with fine-grain sandpaper (zero), and then degrease it with alcohol. The processor cover should also be degreased.

Prepare a cotton swab. From the syringe, squeeze a small ball of Liquid Pro onto the surface, use a cotton swab to push on the ball. The metal will enter the fibers of the cotton wool, and will be held there. Now you need to rub it into the surface with a little effort. If the surfaces are really clean, then the result will not be long in coming. Other methods, such as smearing with a brush or rag, rarely work. In most cases, you will roll the metal in the form of balls until they roll down somewhere, under the processor substrate or simply onto the PCB board (checked).

And when you rub cotton wool over the surface, you remove the thinnest oxide film from the copper, which promotes adhesion.

It should be noted that Liquid Pro is metal and is just a great conductor of electricity. Neither Arctic Silver 5, nor even more so any "silver" in this regard, can not be compared with it. It is necessary to handle this substance very carefully, because one small ball, imperceptibly rolled onto the contacts of a chip, can create a short circuit and permanently disable your entire system. If you work carefully and slowly, and follow the simplest recommendations, precautions, everything will be fine.

For Liquid Pro, the manufacturer indicates a thermal conductivity of more than 80 W / (m x K).

Test results

Based on the data obtained, we divided all samples into five categories, based on the level of thermal conductivity demonstrated by them:

1) worst thermal conductivity (The Worst Thermal Conductivity)

It is not recommended to use pastes in this group in a PC.

2) average thermal conductivity (Medium Thermal Conductivity)

This category includes relatively simple and inexpensive thermal pastes that can satisfy the needs of most users, for whom a couple of "extra" degrees on the processor are not decisive.

3) good thermal conductivity

Thermal interfaces are recommended for demanding users who prefer to use proven products from well-known brands. For this category, the exceptionally high quality and stability of the characteristics of the pastes are in the first place.

4) excellent thermal conductivity (Very Good Thermal Conductivity)

Samples of pastes that fall into this category have impressive characteristics and can be recommended for those who are seriously fond of overclocking or in every possible way want to reduce the temperature of the processor, graphics chip, memory in any way, even by a relatively insignificant amount.

5) Outstanding Thermal Conductivity- the highest, excellent performance among all thermal interfaces.

The substances presented in this category are a worthy choice for those who rightfully consider themselves to be a true enthusiast.

Worst thermal conductivity

Only a few pastes fell into the category of losers. They are the worst of what we have tested, but in comparison with various exotic substances-alternatives to thermal interfaces, they do not look so bad and hopeless:

Frankly speaking, we did not expect such a result, at least from the Titan product. It turns out that the "free" Nano blue was just hopeless ... For the accuracy of the results obtained, this paste was tested several times and consistently showed the worst result.

It is up to each user to decide whether to use the two substances shown in the diagram, but there are a sufficient number of noticeably better products on the market that can often be found in a kit inexpensive systems cooling central processors or in a separate sale, and use them exactly.

Average thermal conductivity

This group is the most numerous. Our standard, KPT-8, also fell into it. On the whole, the paste shows satisfactory characteristics, but it should be noted that in its price range it has practically no obvious competitors.

As it turned out, the viscosity and thermal conductivity of KPT-8 may vary slightly, depending on the specific sample and the place of its production. However, it has very, very little effect on the final result.

In our case, the differences between the existing pastes were only 1 ° C, which is really very little.

I would like to say a few words about AlSil-3. They say that this paste has b O Higher thermal conductivity than other product of the domestic chemical industry, and is positioned as a replacement for KPT-8. But as a result of the tests, any qualitative differences between AlSil-3 and good KPT-8 did not appear, either in terms of the final thermal conductivity, or in the convenience of application and removal. The laboratory site is forced to state the fact that AlSil-3 cannot potentially compete with the "kpt-shka", since it has absolutely no advantages in performance over the latter. In addition, she has b O Higher cost and less common, which makes KPT-8 a better purchase.

This test group included many foreign thermal pastes, which showed satisfactory characteristics and were on par with our standard, and in some cases were slightly better.

All of them are just normal "workhorses", which in no case should be thrown out of the kit of a brand new cooling system and immediately look for a replacement. These thermal interfaces are recommended for those who do not strive to set world records, but still moderately overclock their PC components.

Also in the group of "middle peasants" were many pastes based on metals. The samples shown on the diagram do not justify the hopes placed on them (remember the declaration of the presence of silver in the composition of individual substances and the high declared values of thermal conductivity). They turn out to be no better than a high-quality G8, but contamination of everything and everything when working with such pastes is guaranteed to you.

Good thermal conductivity

As you know, on foreign sites, Arctic Silver products are practically idolized, and in each test they respond with the most flattering words. Recently, there has been a total admiration of users for the new idol in the person of Arctic Silver-5 ...

We have conducted extensive testing to identify the true benefits of this reputable company.

It turns out that Arctic Alumina is no better than Mendeleev's KPT-8.

Alumina got into the Good Thermal Conductivity group exclusively as a stable product High Quality.

The Arctic Silver 3 is a silver-based solution that really outperforms the benchmark by 2 degrees.

Arctic Silver 5 wins already as much as 3 degrees, which is truly an achievement for this series of thermal pastes.

Everything would be fine ... But Arctic Ceramique brings a little chaos into our ranks! It exhibits almost the same characteristics as Arctic Silver 5, and is much easier to apply. And this result is not an error, because tests carried out even after several weeks showed the same result.

In this case, we can definitely say that Arctic Ceramique is a very good buy.

As for Arctic Silver 5, it is effectively sold, partly due to the total belief of users in the power of noble silver;). It is one of the best quality and most successful thermal greases on the market. In addition, the product in question does not cause any difficulties during application and removal, and can be safely recommended to those users who do not seek to save a penny on the purchase of a thermal interface. This group also includes some other pastes from less well-known manufacturers, which will not be an easy task for most ordinary users to get.

Excellent thermal conductivity

First of all, I was pleased with the TTG-G30010 thermal paste from Titan - it not only showed one of the best results in the test (even better than Arctic Silver 5), but also does not suffer from "childhood diseases" inherent in Nano Blue and Silver Grease. If, in addition to everything, we take into account its retail price, then we have a real killer not only of KPT-8, but also of many more effective thermal pastes, regardless of the price of the latter! Gigabyte's nondescript syringe substance, like Apus-TMG 301 and Shin-Etsu MicroSi G-751, also showed impressive results, but they are less common than the above-mentioned product from Titan, so don't use special efforts for their search at points of sale.

Outstanding thermal conductivity

The last group includes the best of the best - thermal pastes, which could not compete with either mass products or other widely advertised and expensive substances.

We have only three pasta champions, and it is difficult to call the most outstanding of them pasta. Coollaboratory Liquid Pro is truly the best thermal interface available today. He demonstrated maximum efficiency and once again confirmed the fame, those legends that already roam the Internet about this product.

Nevertheless, it has a number of significant drawbacks - very high cost, difficulties in application to contact surfaces, electrical conductivity, relatively narrow geography of distribution (mainly large cities-megalopolises). Those who care about every tenth of a degree on the processor, video card chip can easily close their eyes to all the disadvantages inherent in Liquid Pro, but more rational buyers should pay attention to the Arctic Cooling product - MX-1 thermal paste.

What the Swiss company does is often more efficient than competing products, and the thermal interface is no exception. If you look closely at its packaging, you can see on the reverse side a comparison table of the MX-1 with common samples, including Arctic Silver 3. Some of us found it difficult to believe that this paste could compete so well with more eminent competitors. but the testing carried out puts everything in its place.

MX-1 demonstrated a stable result already from the first application - the gap from the standard was not less than 5 ° С!

And what will happen in the indicated 200 hours, which are needed for the paste to acquire optimal condition? To do this, the cooler remained pressed on the stand for exactly 200 hours, every 24 hours the performance of the Swiss product was measured. Unfortunately, in the process of testing on the test bench, the paste only slightly improved its result - by a few tenths of a degree, which does not cause much enthusiasm. Nevertheless, the obvious advantages of the MX-1 are obvious!

The only annoyance with Arctic Cooling is the relative difficulty of applying it to the processor cover and / or base of the cooling system. However, there are far fewer of these downsides than the Coollaboratory Liquid Pro.

Shin-Etsu MicroSi MPU-3.7 also showed a very good result, but there is one "but" - an ordinary user will probably not be able to find such a product. When looking for this substance, you can only rely on luck, no more, so we advise you to pay more attention to other thermal interfaces provided in the Outstanding Thermal Conductivity substance diagram.

Bonus: test of substances that are not thermal interfaces

The natural interest of enthusiasts in looking for adventure has crept into the field of cooling - many overclockers use (or at least try to use) non-standard and exotic substances instead of the usual most pastes. Someone reports about obtaining a very high thermal conductivity, others simply use original substances to stand out from the crowd or avoid going to the market :) In any case, this trend exists. That is why we decided to test how successfully some popular and exotic substances can replace real thermal paste.

Here are the test results for those substances that were tested:

We think that it will not be superfluous to comment on the obtained figures, because the harsh reality spoils the relatively rosy picture depicted in the diagram.

Mustard "Russian"

Yes, the temperature was set exactly at such an interesting numerically value - 66.6 ° С. However, if you wait for a definite long time, it becomes clear that moisture slowly evaporates from this spicy product, and a dry concentrate remains between the heat-distributing cover of the processor and the cooler base. After the test, it can be turned back into normal mustard by adding a little water :).

We hope that none of the sane readers will engage in such experiments on a home computer.

Nefras S4-155 / 200(White Spirit)

Solvent. With it, the test bench sensor at a certain moment recorded a relatively stable heater temperature in the region of 65.5 ° C. True, it is not entirely correct to indicate the obtained value here. The fact is that the heater temperature reached 65.5 ° C, and its growth slowed down, but over time, the digital thermometer readings gradually increased. The reason is simple - the solvent evaporated easily and instead of a heat-conducting substance, after a certain time we would have got an air gap between the processor cover and the cooler base.

Isopropyl alcohol

It turned out to be strange that the temperature when using this substance stopped at 63 ° C (the solvent showed 65 ° C, and their physicochemical properties are very similar). True, after a while the temperature began to rise slowly. As you would expect, the alcohol evaporated.

Machine oil TP-22

It is used for the lubrication of tape drive mechanisms. We will try to use it as a thermal interface. Moreover, it is the various types of engine oils that overclockers often use instead of the usual thermal pastes.

Considering that this is a common mineral oil, the thermal conductivity result was very modest and expected. True, this substance does not evaporate at such temperatures, and besides, it is a good insulator.

Bottom line: as a thermal interface for the TP-22 processor, it is no good.

"Hado"

It resembles Lithol, but has a little the best characteristics; It is used to lubricate various mechanisms, reduces their friction and wear.

On overclockers.ru, many of us have probably read in which the author used Litol instead of paste in his computer.

63.6 ° C is stable. The result is really better than that of mineral oil, but it does not even reach the level of the worst thermal pastes, and therefore it cannot be recommended for use in a PC.

Unrefined food sunflower oil "Yamran" :)

Very interesting. The result was a very persistent (albeit bad) result. Heater temperature - 62 ° C stable.

Petrol

62.5 ° C.

Gasoline evaporates, the temperature rises slowly, as is the case with alcohol.

Low-temperature watch oil MN-30

60.5 ° C is stable. Better now. So we will soon catch up with the worst thermal pastes :)

Pilot Gold, gold-colored marker

For use as a thermal interface, the impregnation contained in the inner fiber "core" was used. 57.5 ° C is a very good result, but since the marker dye is alcohol-based, the temperature during testing turns out to be unstable and slowly rises as the substance evaporates.

Toothpaste "Pearl"

So, let's try to fake the classic white thermal paste. They say that KPT-8 and AlSil 3 are substituted with cheap toothpaste. Comparison will show how true these beliefs are!

A clear smell of menthol, and the consistency is not the same. You would surely distinguish any toothpaste from CBT-8 :)

The test result is 55.5 ° C! We couldn’t believe our eyes - this is a true CBT-8! In terms of efficiency, it is even slightly better than our standard.

No wait. Do not run to smear processors with toothpastes! The result will be unstable in any case, because any dentifrice contains water, and it evaporates over time, and the temperature of the heater slowly rises. The paste becomes a heat insulator, turning into a kind of chalk.

Drinking water

54 ° C.

Look, the water turned out to be 2 degrees better than our standard! The H20 really does wonders. Without water, there would be no life on our planet. True, one cannot escape the laws of physics: the eternal cycle of moisture in nature spoils everything ... Water evaporates and the temperature of the heater rises over time. Therefore, it cannot be used as a thermal interface. In addition, even when conducting tests "for the sake of sports interest" in a real computer, there is a risk of flooding the space around the socket, which can lead to a short circuit and failure of PC components.

Summing up the intermediate result, it should be noted that we have obtained very interesting results. Nevertheless, in any case, do not rush to change the standard thermal paste in your computer for toothpaste, or, worse, fill the processor cover with water! On special equipment, protected from short circuits, and for short-term tests, we could afford it.

In addition, there is one important point: the overwhelming majority of substances considered in this section contain alcohol or water (or they are). When the heat collector heats up, they evaporate very intensively, which leads to the complete "self-destruction" of the used thermal interface!

Also, some substitutes may contain chemically active substances that cause corrosion of the soles of a cooler or water block! A prime example of this is proven toothpaste. At first, it demonstrates a result that is better than that of KPT-8, but after an hour or two while the computer is running, the moisture contained in it almost completely evaporates, and the "Pearl" turns into a heat insulator! Having removed the cooler from the processor after such a test, you will see that its copper base is covered with a dark coating, which can only be removed by grinding. Therefore, in order to avoid trouble, in no case repeat tests like ours at home!

Conclusion

Testing is over - it's time to summarize. For greater clarity of the results obtained, the indicators of all thermal pastes are displayed on one summary diagram:

Absolute test leader, liquid metal-based thermal interface Coollaboratory Liquid Pro, is awarded a badge of honor for outstanding performance indicators Certified Hardcore website:

Remembering a number of its features, which can easily be called shortcomings, we decided to note another thermal interface, Arctic Cooling MX-1, a similar award, Certified Hardcore website:

It is much more like the usual thermal paste than "liquid metal", is widespread and has almost no drawbacks.

Product TITAN COMPUTER CO. LTD., Nano Grease TTG-30030, due to mass availability, democratic cost and very high efficiency, has earned an award King of the Hill website:

Finally, you need to focus on the fact that in front of you is a clear comparative test set of thermal interfaces using a single method, on a stable heat source under the same conditions.

We cannot speak with 100% certainty about the truthfulness or objectivity of the results obtained, just as we cannot speak about the reliability of tests on a real central processor. On many real systems, the results differ slightly due to the variability of conditions and the influence of many accompanying factors on the research process itself, therefore it is not possible to make an unambiguous and only correct conclusion.

Be that as it may, the results obtained clearly demonstrate the difference between individual thermal interfaces, and they should not be ignored. We have made every effort to present you with a subjective reflection of the objective truth about the effectiveness of various heat-conducting pastes!

Readers should remember that in many respects the repetition of the results obtained on the test bench, in the case of tests on the central processor, will depend on the architecture of the latter, the features of the built-in thermal sensor, and, first of all, on the level of heat dissipation. So, at TDP = 35 W the difference between the best and worst pastes will be very small(one or two degrees), and only with an increase in this indicator (especially when overclocking powerful CPUs) will it manifest itself in the maximum volume.

We hope that now those who had never even imagined the existence of a substance called thermal paste in their computer, now have some reasons for thought, supported by an appropriate test base.

True, it is not at all necessary to remove the cover immediately after reading this material. system unit, dismantle the cooling system and change the substance that was originally smeared on the processor's heat dissipator. It is necessary to soberly weigh the pros and cons, and think whether there is really a practical need for such a course. Those who operate their computer in nominal mode have nothing to worry about, even if the assembler used the worst thermal interface (however, there are times when a seemingly qualified engineer of a reputable company not only does not apply thermal paste to the processor cover, but even forgets to remove the protective plastic wrap from the base of the cooling system!).

For those who are really worried about every extra degree on the processor, and / or are busy squeezing out the last megahertz from their favorite iron, when looking for a specific thermal interface, first of all, it is necessary to take into account their needs and the actual availability of some kind of paste. Factors that will facilitate the purchase are ease of application and rinsing, and, of course, price.

I would also like to note that working with thermal interfaces is not dangerous if you only sometimes use these substances, and do not deal with them around the clock. When applying / removing pastes, it will not be superfluous to have alcohol and napkins on hand. It is advisable not to smear the thermal interface on the skin, because in some cases, too much of a certain substance can cause an allergic reaction, but the rejuvenation of the body is unlikely :)

Repeating the already classic replica, in the end we will say: if you have a desire to change the cooling system, first you should ask yourself: “... maybe, for a start, it would be better to just change the thermal interface?”.

Thermal pastes Arctic Ceramique, Arctic Cooling MX-1 and Coollaboratory Liquid Pro are provided by PCForsage online store.

Reviews, wishes and comments on this material are accepted in the forum site.

ALL ORDERS WHICH ARE WAITING FOR PAYMENT WILL BE AUTOMATICALLY CANCELED WITHOUT PRIOR NOTICE AFTER DAYS.

In our online store, the price of goods indicated on the site pages is final.

The procedure for payment by electronic money, bank card, from a mobile account:

- After placing your order, your order will be placed in your Personal Area with status " Pending verification"

- Our managers will check the availability in the warehouse, and put the goods you have chosen in reserve. At the same time, the status of your order is changed to " Paid". Next to status" Paid"a link will be displayed" Pay"by clicking on which you will be taken to the page for selecting payment methods on the Robokassa website.

- After choosing a method and making payment for the order, the status will automatically change to " Paid". Further, as soon as possible, the goods will be sent to you by the delivery method selected in the process of ordering.

1. Payment in cash

It is possible to pay in cash for the purchased goods to the courier (delivering your goods), or in the store (in case of self-pickup). If you pay in cash, you will be given a sales receipt, a cashier's receipt.

ATTENTION!!! Cash on delivery DOES NOT WORK, therefore, payment upon receipt of the parcel is not possible!

2. Payment by bank transfer

For legal entities we have provided the opportunity to pay for purchases using a cashless payment. In the process of placing an order, select the cashless payment method and enter the data for invoicing.

3. Payment through a payment terminal

ROBOKASSA - allows you to accept payments from customers usingbank cards, at any electronic currency, using servicesmobile commerce(MTS, Megafon, Beeline), payments viaInternet bankleading banks of the Russian Federation, payments through ATMs, throughinstant payment terminalsand also usingiPhone apps.

Heat-conducting paste has the form of a plastic substance with high thermal conductivity. Its purpose is to improve the heat exchange processes between the radiator and the processor. If you are interested and want to know more, then proceed to reading the article.

Why do you need thermal paste "KPT-8"

Thermal paste "KPT-8" is made in the form of a homogeneous paste of white or gray color, sometimes it is blue or silver. In the past, processors were made of cold type, so this substance was dispensed with. Currently, such a paste is needed by anyone, even a low-power processor unit. Overclocking of modern processors is provided by manufacturers, this is achieved through programming, the user will need to make changes to the settings using the BIOS Setup utility. Due to the presence of microroughnesses in the processor and heatsink, an air gap forms, which reduces the heat dissipation of the microprocessor. This problem is very urgent at the present time, since many units operate at the limit of their capabilities, while intense heat is generated.

How to use thermal paste correctly

The paste is squeezed out of the tube in a straight line, from one edge to the other on one side of the processor surface. You need to make sure that the line is not too thin, but you should not make it too wide. A layer that is too thick will not work. According to reviews, "KPT-8" thermal paste is squeezed out poorly and unevenly in the syringe, so it is better to purchase it in a factory tube.

Taking the card in hand, press its edge behind the paste so that it bends. Slowly spread from right to left and apply intense pressure to spread the paste.

You can get a good result from just one try. But if you need to repeat the procedure, the paste will need to be removed, or with the help of a card, you can even out the resulting gaps. To achieve a thin, even layer, you will need to walk over the applied paste with a card several times.

What is important to know more about thermal paste

The secret to applying the paste correctly is extremely simple. It is imperative to remove excess paste that is not on the surface of the processor. This is done using a rag.

It is important not to allow the substance to come into contact with motherboard, this can lead to undesirable consequences. Therefore, the procedure must be carried out very carefully. After all, excess paste that fell on the wrong elements can cause malfunction. There is no need to apply paste to the cooler radiator. You don't need to do two layers either. Many reviews of KPT-8 thermal paste for a laptop do not recommend it because of its low thermal conductivity, so your device may simply burn out from overheating.

Characteristics of the thermal paste "KPT-8"