Repair of audio amplifiers

To repair the ultrasonic frequency converter, the following devices are required: a sound generator of the type GZ-102, GZ-118, an oscilloscope of the type C1-78, C1-83 or similar, a nonlinear distortion meter C6-5, a universal voltmeter of type B7-27 or the like, load equivalents 4 , 8, 16 Ohm of the corresponding power. Wirewound resistors can be used as equivalents. For the repair of high-quality ultrasonic frequencies and their subsequent adjustment, a sound generator with a precision signal waveform, a low-frequency spectrum analyzer and an amplitude-frequency characteristics meter are desirable.

External manifestations of amplifier malfunctions are as follows: periodic loss of sound or its complete absence, a weak output signal level, a high level of noise or background, nonlinear distortions.

A malfunction in which there is a loss of signal, crackling and other noises at the time of adjusting the signal level is usually associated with contamination of the movable contact of the adjustment potentiometer. The defect can be eliminated by disassembling the regulator and wiping the contact. If the malfunction cannot be eliminated, the potentiometer is replaced.

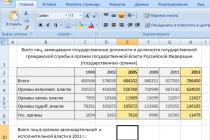

The algorithms for finding faults of the ultrasonic frequency converter are based on a sequential check of the signal flow and analysis of the operability of the amplifier stages (a method of sequential intermediate measurements from input to output). When diagnosing the ultrasonic frequency converter by the method of exceptions, the serviceability of the cascades from the output towards the input is checked. For powerful ultrasonic frequencies, the second method is preferable. In low-power amplifiers (up to 5 W) and pre-amplifiers, both methods of finding a defect can be used. A faulty element in a cascade is determined by measuring the modes and comparing them with nominal or checking resistances and comparing them with a resistance map. The fault finding algorithm for a full audio frequency amplifier (see block diagram in Fig. 5.1) is shown in Fig. 5.9.

In the event of a malfunction of one channel of a stereo amplifier, to localize the faulty stage, it is possible to recommend paralleling the input circuits of similar stages through a blocking capacitor.

The determination of the malfunction of the ULPTsT (I) UZCH TV is carried out according to the algorithm (Fig. 5.10, o), compiled on the basis of the exception method. The algorithm for diagnostics of the Amfiton 002 amplifier was obtained in a similar way (Fig. 5.10, b). Malfunctions of the ultrasonic frequency converter in integral design are established by comparing the voltages at the microcircuit terminals with the nominal ones. The discrepancy between the modes indicates the defectiveness of the microcircuit.

UZCH parameters are monitored according to the functional diagram shown in Fig. 5.11. In this case, the nominal output power at a frequency of 1000 Hz can be determined by the expression P = U2 / R ".

The frequency response of the amplifier is plotted point by point when the frequency of the input voltage of the amplifier changes with the output voltage being fixed. The tone control limits are set in the same way.

The process of controlling the frequency response of the amplifier is greatly simplified in the presence of a frequency response meter of the XI -49 type or the like. Having connected the amplifier to the meter, the amplitude-frequency characteristic is observed on its screen.

If the harmonic distortion is less than 0.1%, then its measurement is fraught with significant difficulties, since the industry does not produce harmonic distortion meters with such a resolution.

42 43 44 45 46 47 48 49 ..Tuning and adjustment of ultrasonic frequency

In order to properly adjust the ultrasound frequency, you need to have a clear idea of the purpose and role of all the elements included in it, understand the physical processes occurring in amplifiers, and be able to competently use measuring instruments.

After checking the performance of the ultrasonic frequency converter, the modes of the amplifying elements (transistors - or microcircuits) are checked in stages by direct current and they begin to set up and adjust the amplifier. The task of adjusting and adjusting the ultrasonic frequency converter is to ensure the production of amplifiers that comply with the standard or technical specifications, with the help of certain technological and control operations, for example, establishing the optimal operating modes of individual elements (transistors, microcircuits), identifying and eliminating malfunctions.

Before starting measurements, check the power consumed by the ultrasonic frequency converter in the absence of a signal at its input. To do this, the switch is moved to position II (see Fig. 65). The power consumed by the ultrasonic frequency converter is determined by a voltmeter V and an ammeter A, included in the amplifier's power supply circuit. According to the readings of these instruments, the consumed current I0 and the voltage of the power supply 11 are determined. The accuracy class of the measuring instruments must be at least 2.5. The consumed ultrasonic power is calculated by the formula: Ppotr = I0Eist

To the input of the ultrasonic frequency converter most often to the corresponding terminals of the "Tape recorder" connector from the sound generator, a nominal signal voltage at a frequency of 1000 Hz is supplied, corresponding to the nominal power in the load. At the output of the ultrasonic frequency converter, measuring instruments are connected in parallel to the voice coil of the loudspeaker: an electronic voltmeter 6, an oscilloscope 7 and a nonlinear distortion meter 8.

Make sure the gain controls are working correctly. For this, the volume control is set to the position of maximum amplification, and the signal voltage at the input of the stage is increased until the output of the ultrasonic frequency converter is obtained at a voltage corresponding to the rated output power. Then the volume control knob is set to the minimum gain position (within the limits of smooth adjustment) and the output voltage is determined again. The ratio of both voltages at the output of the ultrasonic frequency converter, expressed in decibels, characterizes the depth of the volume control and must comply with the specifications.

The cascading ultrasonic frequency control begins with the final stage. In the circuit shown in fig. 62, the input signal from the sound generator through the capacitor Cp goes to the base of the transistor V. The cascade mode will be determined by the voltage of the power supply Ek, the constant bias voltage Ubeo at the base of the transistor, the voltage drop across the resistors R2 and R0 in the emitter circuit, which serves for thermal stabilization of the amplifier.

The establishment of such a cascade of the ultrasonic frequency converter is reduced to adjusting the collector current of the transistor by selecting the resistor R2, while simultaneously measuring the voltage Ubeo, which is determined by the specified mode of the transistor. Checking the cascade for nonlinear distortions using an oscilloscope is carried out by applying a nominal signal voltage at a frequency of 1000 Hz from the sound generator to the input of the final stage. In this case, the gain should be maximum. If the ultrasonic frequency converter is working properly and works without nonlinear distortions, an undistorted shape of the output signal can be observed on the oscilloscope screen.

When the input signal level is increased, non-linear signal distortions will appear at the output. In fig. 66 shows oscillograms of the change in the shape of the sinusoidal curve of the signal at the output of the ultrasonic frequency converter at various values of nonlinear distortion (8, 12, 15 and 20%). To observe a low-frequency signal, the oscilloscope sweep frequency is selected in the range of 200-500 Hz.

If, at the nominal input signal, the stage introduces nonlinear distortion (the waveform in the load is distorted), the operating mode of the stage is changed. By changing the collector current (by changing R2, see Fig. 62), the absence of nonlinear distortions is achieved.

Rice. 66. Oscillograms of changes in the shape of the sinusoidal curve of the signal at the output of the amplifier at various values of nonlinear distortion

The tuning of push-pull output stages begins by supplying the signal voltage from the generator to the phase-inverted stage. Preliminary adjustment of the push-pull final stage of the ultrasonic frequency converter (see Fig. 64) on transistors is carried out by selecting identical transistors or by adjusting the bias voltage using resistors 1-R13 and 1-R14 in the base circuits. The condition for the normal operation of the push-pull final stage is the symmetry of its arms with respect to direct and alternating currents. It should be remembered that the lack of symmetry of the arms leads to the appearance of harmonic distortion and a decrease in the dynamic range of the amplifier due to poor compensation of the AC hum, noise, etc.

Adjustment of phase-inverted cascades (see Fig. 61) consists in setting the same values of the output voltage, shifted one relative to the other by 180 °. This is done by selecting the resistances of the resistors in the collector and emitter circuits. Setting up the preliminary stages of the ultrasonic frequency converter is to ensure the typical mode of operation of the transistors by selecting the resistances of the resistors R2 and R3 (see Fig. 60).

The final stage of establishing an ultrasonic frequency response is to select the elements of the negative circuits. feedback... If, in the process of adjusting the preliminary stages of the ultrasonic amplifier, it turns out that the sensitivity of the amplifier is too high, the gain can be reduced by introducing deeper feedback.

In some cases, to obtain the most pleasant sound, the frequency response is corrected by low frequencies ah selection of transition capacitors. Rated capacity

There should be enough crossover capacitors for low frequencies to be reproduced well. Changing the tone of the sound using the tone control should be smooth.

The playback volume with a working regulator should also change smoothly from maximum to minimum. If, when the knobs of the variable resistors (volume and tone controls) are rotated, crackles and rustles are heard, these resistors should be replaced. At maximum volume in any position of the tone control, the amplifier should not self-excite.

The final stage of establishing an ultrasonic frequency amplifier is its testing and verification of all quality indicators: the level of intrinsic noise (background), nonlinear distortions, rated output power, reproducible frequency range and uneven frequency response.

Making sure of normal work UZCH, remove the amplitude-frequency response (for example, with an oscilloscope). If on

Apply the nominal signal voltage to the input of the ultrasonic frequency generator from the sound generator; the oscilloscope screen displays fluctuations in the output voltage. When you turn the knob for tuning the frequency of the generator along the audio frequency range, you can see on the oscilloscope screen that different levels of the output voltage will correspond to a constant voltage level of the input signal.

It should be noted that the circuits shown in Fig. 8.14, are designed to convert input signals of positive polarity only. If it is necessary to process input signals with negative polarity, you can reverse the direction of switching on the diodes. To process positive and negative input signals in one device, two counter-connected nonlinear elements are used. Bipolar transistors (their emitter-base junctions) can be used as nonlinear elements. In this case, the range of processed signals can be increased by one or two orders of magnitude and the processing accuracy can be increased, but at the same time the complexity of the device also increases. Amplifiers (see figure 8.14) are commonly used in multiplying and dividing analog signals.

and in noise canceling devices in audio frequency amplifiers.

9. ADJUSTMENTS IN AMPLIFIERS

9.1. General Provisions

V Depending on the technical specifications for the amplifier and its functional purpose, the amplifying device can provide for adjustments of a wide variety of parameters: amplifying properties, frequency properties in the passband and the width of the passband itself, phase characteristics, dynamic range, input and output impedances

and etc. All of these adjustments can be manual or automatic. Decisions about the need to use manual adjustments, about their depth in each specific case are made and carried out by the operator servicing the amplifier. Automatic adjustments are carried out in the amplifier independently under the influence of changes in the specified operating conditions. Adjustments can be smooth, when the controlled parameter changes smoothly and continuously, and discrete, when the controlled parameter changes by jumps. In addition to permanent adjustments, trimmers can be introduced into the amplifier circuit, which are used during the initial setup, repair or maintenance work. The most commonly used amplifiers are gain adjustments and frequency response adjustments. The latter, when used in amplifiers of audio signals, are called tone controls.

9.2. Gain control

Purpose of the gain controls:

protection of the amplifier from overloads in the event that dynamic range the signal exceeds the dynamic range of the amplifier;

maintaining a constant value of the gain when replacing active elements, aging amplifier parts, changing supply voltages, etc.;

changing the value of the output signal within the required limits.

For the purpose of changing the gain, a potentiometric voltage divider, variable depth feedback and changing the operating mode of active elements can be used.

Potentiometric gain control can be discrete and smooth (Fig. 9.1).

The principle of operation in both regulators is the same. The u2 output is highlighted on the lower arm of the divider. According to the second Kirchhoff's law, its value is proportional to the amount of resistance that forms the lower shoulder. The transfer coefficients of the discrete and smooth controller, respectively, have the form

K D = u 2 |

(R 2 + R 3) |

; KP = |

||||||

R 1 + R 2 + R 3 |

||||||||

R1 + R 2 |

||||||||

A discrete regulator turns out to be usually more complicated than a smooth one and is most often used in measuring equipment.

If the gain regulator is to operate in a wide frequency band, then it is necessary to take into account the reactive elements connected to the lower arm of the divider. Such a regulator, as a rule, is built according to a parallel circuit (Fig. 9.2), assembled from several dividers with appropriate division ratios.

The input capacitance of the next stage is connected to the lower arm of the divider, which leads to the frequency dependence of the transmission coefficient. In this case, the impedance of the lower arm decreases with increasing frequency, and with the active resistance of the upper arm, the division coefficient decreases with increasing frequency. To maintain constant odds

The transmission of the divider in the entire frequency range has to be shunted by an additional capacitance, which is selected from the condition that the time constants of the upper and lower arms are equal.

u 1 R 2 |

C 2 R 4 |

So, for the step controller shown in Fig. 9.2, the following equalities must be respected:

R 1C 1 = R 2C 2 and R 3C 3 = R 4C 4. |

To facilitate the adjustment of such dividers in the tank, shunting both the lower and upper arms usually include trimmer capacitors.

Nowadays, step regulators have begun to be widely used in amplifiers of audio frequency signals. The division step in this case is

taken small (1 - 2dB), and mechanical switches are replaced by

boron electronic keys, the state of which is recorded by the storage device.

Smooth gain control is carried out using variable resistances used as signal voltage dividers (see Fig. 9.1, b). When designing volume controls for amplifiers of audio frequency signals, it is necessary to additionally take into account the peculiarities of human auditory perception. The human ear is designed in such a way that a person's sensation of sound volume is proportional to the logarithm of the signal level. Therefore, if we take as a volume control a variable resistor with a linear dependence of resistance on the position of the slider, it will seem that the volume grows very quickly at the very beginning of the slider's turn and hardly changes during the entire second half of its movement. The use of a resistor with an exponential law of resistance change depending on the position of the slider allows you to get the feeling of a uniform change in volume, proportional to the angle of rotation of the slider. True, to obtain such a dependence in practice, comparatively small resistances, which shunt the regulator from the signal source and load, and violate the necessary law of resistance change, interfere with obtaining such a dependence.

The second feature of regulators |

||||

CH |

SV |

loudness is associated with a change in the frequency |

||

sensitivity of the human ear due to |

||||

change the volume of the signal. The fact is that |

||||

with a decrease in the level of the signal sensitivity |

||||

ear to the upper and lower frequencies of the |

||||

labors. This weakening is increasing rapidly |

||||

with decreasing volume. Therefore, for co- |

keeping a uniform frequency response of sound perception when decreasing the volume level, it is necessary to reduce the signal at the middle frequencies more than at the lower and higher frequencies. This effect is achieved by using loudspeaker volume controls (fig. 9.3). In this regulator, additional frequency response correction circuits are introduced. The CB capacitor performs high frequency correction. The CB capacitance is chosen small and therefore does not have any effect on the low and medium frequency range. At high frequencies, the impedance of the upper arm of the divider decreases, which provides

the rise of the frequency response at these frequencies in relation to the mid-frequency region. The time constant of the serial connection CH RH is chosen in such a way that this chain shunts the lower arm of the divider in the region of middle and higher frequencies and thereby creates a relative rise for the low-frequency components of the signal spectrum. As you move the middle pin of the potentiometer downward, this bulging effect of low and high frequencies in relation to the mids increases. The depth of the level control, estimated as the ratio of the signal levels at the extreme positions of the knob, for the volume control described above lies within 35 - 45 dB.

A smooth change in the signal level at the amplifier output can be carried out by changing the operating mode of the active element or the depth of the feedback. Examples of such schemes are shown in Fig. 9.4.

V diagram in fig. 9.4, and a smooth gain adjustment is made by changing the position of the operating point. Increase in resistance R P leads to a decrease in the current through the transistor, a decrease in its slope and, consequently, the gain of this stage. The depth of adjustment is limited by the fact that with a significant decrease in the emitter current, additional nonlinear distortions appear and the influence of intrinsic noise increases.

V diagram in fig. 9.4, b variable resistance R P creates local negative current feedback in series with the AC input. The depth of the feedback and, accordingly, the gain depends on the value of the resistance RP. If, in the previous circuit, the ESS capacitor is connected only in parallel with the resistance RE, then both methods will operate in it and the depth of adjustment will increase significantly.

Gain control by changing the position of the operating point (see Fig. 9.4, c) is widely used in automatic gain control (AGC) systems. In this case, the control voltage UUPR is supplied to the base divider circuit, the value of which is determined by the value of the output signal.

SE |

||||||

R and R D |

R and R D |

|||||

U UPR |

||||||

When the output signal increases under the influence of the input one, the voltage UUPR locks the transistor, and when it decreases, it opens, maintaining the output voltage constant with very significant changes in the signal at the input.

It should be noted that all of these gain control methods work equally well in bipolar and field-effect transistor amplifiers.

Reverse depth change |

|||||||||||||

connection in order to change the coefficient |

|||||||||||||

Gain tape is widely used |

|||||||||||||

in amplifiers on op amps. To carry out |

|||||||||||||

making such an adjustment is one of the |

|||||||||||||

feedback resistance |

|||||||||||||

make it variable (see fig. 9.5). |

|||||||||||||

In fig. 9.5, and presented by re- |

|||||||||||||

op-amp regulator with inverting |

|||||||||||||

entrance. Changing the position of the floor |

|||||||||||||

the RP resistance indicator results in

a change in the depth of feedback and, accordingly, to a change in the gain. At the same time, a change in the feedback depth entails a change in the input and output resistances. The difference between the circuit (see Fig. 9.5, b) from the previous one is that it uses a non-inverting op-amp connection.

Of particular interest is the diagram in Fig. 9.6. The variable resistance has two functions here. Changing the position of the slider leads to a change in the signal level at the input of the op-amp and, at the same time, to a change in the feedback depth. Thus, the dependence of the transfer coefficient on the angle of rotation of the potentiometer becomes indicative, and a regulator with a linearly varying resistance can be used in the circuit.

Interference due to instability of the moving contact can be avoided by using voltage or current-controlled resistors instead of a mechanical regulating element. Field-effect transistors and optocouplers are used as such controlled variable resistances. The channel resistance of the field-effect transistor is linearly dependent on the voltage between the gate and the source, as evidenced by the family of output characteristics, fanning out when the voltage on the drain is close to zero. By including such a resistance as the lower arm of the divider in the feedback circuit (Fig. 9.7, a), and changing the control voltage at the gate UUPR, you can adjust the depth of the feedback and, accordingly, the gain. With an increase in the negative control voltage at the gate, the channel resistance increases, the depth of the reverse

UUPR

R OS

U UPR

A change in the current through the diode under the influence of the voltage UUPR leads to a change in the resistance of the optocoupler connected to the upper arm of the feedback circuit divider, and, accordingly, to a change in the gain. Such schemes are very convenient for creating automatic systems gain control and systems remote control gain.

The place where the regulator is included in the circuit (smooth and discrete) is determined by several conditions.

C P2

C P1

To prevent the amplifier from overloading and so that nonlinear distortions do not occur in the first stages, it is advisable to place the gain regulator as close to the input as possible. However, if the volume control is turned on at the input of the first stage, then in this case with

A low frequency amplifier (ULF) is a device every music lover knows about its purpose. This component of the audio system improves the overall sound quality of the acoustics. But like any other electronic devices, AU can fail. For more information on how to repair amplifiers of car audio systems with your own hands, learn from this article.

[Hide]

Typical malfunctions

Before repairing, installing and adjusting the ULF in your car, you need to understand the breakdown. It is simply impossible to consider all the faults that can be encountered in practice, since there are a lot of them. The main task of repairing a device for sound amplification is considered to be the restoration of a broken component, the breakdown of which led to the inoperability of the entire board.

In any electrical engineering, including amplifiers, there can be two types of faults:

- contact is present where it should not be;

- in the place where the contact should be, it is absent.

Functional check

Repair of car amplifiers first of all starts with ULF diagnostics:

- First you need to open the case and carefully examine the circuit, use a magnifying glass if necessary. During diagnostics, you can notice the destroyed components of the circuit: resistors, capacitors, broken conductors or burned-out paths of the board. But if you find a burnt-out component, you need to take into account that its failure may be the result of the burnout of another element, which in appearance may seem whole.

- Next, diagnose the power supply, in particular, check the output voltage. When identifying burnt-out resistors, these elements will need to be changed.

- Apply power to the ULF and the Remout output, then you need to close the system to plus and look at the PROTECTION diode indicator. If the light comes on, this indicates that the device has gone into protection. The reason may be poor power supply or its absence on the board, transistor breakdown, or problems in the operation of the voltage converter. In some cases, the reason lies in the breakdown of a transistor power amplifier for one of several channels.

- If after power was applied, the safety element does not burn out, you need to check the voltage level at the output. It should be approximately 2x20 in or more.

- Carefully inspect the transformer device of the voltage converter; it may have burnt-out turns or open circuits. Smell this element, maybe it smells burnt. In some ULF models, a diode assembly is installed between the PN output and the amplifier - if it fails, the unit can also turn on protection.

Elimination of breakdowns

Do-it-yourself car amplifier repair is carried out in accordance with what problem was identified during its operation:

- If the transistor in the car amplifier breaks down, then before directly replacing it, it is recommended to diagnose the safety element by power supply. You also need to make sure that the diodes on the buses are working. If everything is in order with these parts, the installed transistors must be replaced.

- For more specialized repairs, you need an oscilloscope. Having installed the probes of the device on pins 9 and 10 of the generator board, you need to make sure that there are signals. If the signals are absent, then the driver changes, if they are, then the field-effect transistor elements are replaced.

- Capacitors are changed much less often during the repair process - as practice shows, this does not happen often (the author of the video is the HamRadio Tag channel).

Basic aspects of amplifier tuning

Now let's move on to the question - how to set up a car amplifier? There are several configuration options - for use with and without a sub.

How to properly configure the ULF without a subwoofer - first you need to set the following parameters:

- bass boost - 0 decibels;

- level - 0 (8V);

- the crossover must be set to FLAT.

After that, adjusting the settings of the audio system with an equalizer, the system is tuned to suit your preferences. The volume must be set to maximum and include some track. How to set up for use with a subwoofer is also not particularly difficult.

For correct setting it is advisable to use the following parameters:

- Bass Boost should also be set to 0 decibels;

- the level is set to 0;

- the front crossover is set to the НР position, and the FI PASS control element must be set in the range from 50 to 80 Hertz;

- for the rear crossover, it is set to LP, and the Low control must be set between 60 and 100 Hertz.

It is very important to observe these parameters, since they determine the quality of the adjustment and, accordingly, the sound of the audio system. In general, the setup procedure is similar, using the level control to provide a more harmonious sound. The sensitivity of the rear and front speakers should be matched to each other.

Sorry, there are currently no polls available.If you don’t understand anything about this, it’s better not to go there, because repairs will cost more after you burn or break it.

Change the quiescent current of the cascade, depending on the type of cascade, either the base current of the transistor, or the bias voltage on the lamp grid.

To create base current for a common-emitter transistor, use a resistor that connects the base to either the supply rail or the collector. The second is preferable from the point of thermal stabilization. The lower the resistance of the resistor, the greater the base current, a, and the quiescent current of the stage. There are other, more advanced thermal stabilization schemes for bipolar ones, involving the use of several resistors.

To create a bias voltage of the lamp, connect its control grid to a wire through a high-resistance resistor (you do not need to change its value), and connect a resistor between the cathode and the common wire, with which the bias voltage will be regulated. Shunt it with a capacitor (if it is electrolytic, turn it on with a plus to the cathode). The greater the resistance of the cathode resistor, the greater the blocking voltage on the grid, which is negative with respect to the cathode (but not the common wire), and, accordingly, the lower the quiescent current of the stage.

If the stage is used for AC amplification, apply the input signal to it through a very low leakage capacitor so as not to disturb its DC operation. Remove the output signal from the load also through a capacitor.

Regardless of whether the stage is a tube or a transistor one, first take a resistor that sets the quiescent current, a large resistance, so that this current is small. Apply a signal to the input of the stage through a capacitor so that its distortion can be easily detected by ear or on the oscilloscope screen. Take the output signal also through a capacitor, and apply it, respectively, to a control amplifier or an oscilloscope. Install the transistor on the heat sink in advance.

Connect a milliammeter in series with the pull-up resistor. Only then supply power to the cascade. The quiescent current will be small and the distortion will be large.

Each time before turning off the power supply of the cascade, put in it a resistor of less and less resistance. The quiescent current will increase distortion - decrease. When they stop falling, stop lowering the resistance. Do not try to find out in practice what will happen with its further decrease - believe a word: the gain will begin to fall, the quiescent current will increase to unacceptable of great importance, the active element may fail.

If you are satisfied with the increased power consumption of the stage, leave the quiescent current at a blue level, and if you want to sacrifice the quality of amplification for the sake of economy, reduce the quiescent current to the desired level.