The mass market entry of compact zinc air batteries has the potential to make a significant difference in the small-sized battery pack for laptop computers and digital devices.

Energy problem

and in recent years, the fleet of portable computers and various digital devices has grown significantly, many of which have recently appeared on the market. This process has accelerated markedly due to the increasing popularity of mobile phones. In turn, the rapid growth in the number of portable electronic devices has caused a serious increase in demand for autonomous sources of electricity, in particular for various types of batteries and accumulators.

However, the need to provide a huge number of portable devices with batteries is only one side of the problem. So, with the development of portable electronic devices, the assembly density of the elements and the power of the microprocessors used in them increase - in just three years the clock frequency of the used PDA processors has increased by an order of magnitude. Tiny monochrome screens are being replaced by high-resolution, larger-screen color displays. All this leads to an increase in energy consumption. In addition, there is a clear trend towards further miniaturization in the field of portable electronics. Taking into account the above factors, it becomes quite obvious that an increase in energy intensity, power, durability and reliability of the used batteries is one of the most important conditions for ensuring the further development of portable electronic devices.

The problem of renewable sources of autonomous power supply is very acute in the segment of portable PCs. Modern technologies make it possible to create laptops that are practically not inferior in their functional equipment and performance to full-fledged desktop systems. However, the lack of sufficiently effective sources of autonomous power supply deprives laptop users of one of the main advantages of this type of computer - mobility. A good indicator for a modern laptop equipped with a lithium-ion battery is a battery life of about 4 hours 1, but this is clearly not enough for full-fledged work in mobile conditions (for example, a flight from Moscow to Tokyo takes about 10 hours, and from Moscow to Los Angeles - almost 15).

One of the options for solving the problem of increasing the battery life of portable PCs is the transition from the now widespread nickel-metal hydride and lithium-ion batteries to chemical fuel cells 2. Low operating temperature fuel cells such as PEM (Proton Exchange Membrane) and DMCF (Direct Methanol Fuel Cells) are the most promising for applications in portable electronic devices and PCs. An aqueous solution of methyl alcohol (methanol) 3 is used as fuel for these elements.

However, at this stage, it would be too optimistic to describe the future of chemical fuel cells exclusively in pink colors. The fact is that at least two obstacles stand in the way of the mass distribution of fuel cells in portable electronic devices. Firstly, methanol is a rather toxic substance, which implies increased requirements for the tightness and reliability of fuel cartridges. Secondly, catalysts must be used to ensure an acceptable rate of passage of chemical reactions in fuel cells with a low operating temperature. Currently, catalysts made from platinum and its alloys are used in PEM and DMCF cells, but the natural reserves of this substance are small and its cost is high. It is theoretically possible to replace platinum with other catalysts, but so far none of the teams engaged in research in this area has been able to find an acceptable alternative. Today, the so-called platinum problem is perhaps the most serious obstacle to the widespread adoption of fuel cells in laptop PCs and electronic devices.

1 This refers to the operating time from the standard battery.

2 Read more about fuel cells in the article "Fuel Cells: A Year of Hope" published in # 1'2005.

3 PEM cells fueled by gaseous hydrogen have an integrated converter for the production of hydrogen from methanol.

Zinc air cells

Although the authors of a number of publications consider zinc air batteries and accumulators to be one of the subtypes of fuel cells, this is not entirely true. Having familiarized yourself with the device and the principle of operation of zinc-air cells, even in general terms, one can make a completely unambiguous conclusion that it is more correct to consider them as a separate class of autonomous power supplies.

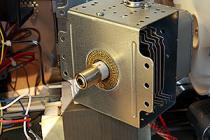

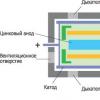

The zinc air cell cell design includes a cathode and an anode, separated by an alkaline electrolyte and mechanical separators. A gas diffusion electrode (GDE) is used as the cathode, the permeable membrane of which allows oxygen to be obtained from the atmospheric air circulating through it. The "fuel" is the zinc anode, which is oxidized during the operation of the cell, and the oxidizing agent is oxygen obtained from the atmospheric air entering through the "breathing holes".

At the cathode, the reaction of electroreduction of oxygen occurs, the products of which are negatively charged hydroxide ions:

O 2 + 2H 2 O + 4e 4OH -.

Hydroxide ions move in the electrolyte to the zinc anode, where the zinc oxidation reaction takes place with the release of electrons, which return to the cathode through the external circuit:

Zn + 4OH - Zn (OH) 4 2– + 2e.

Zn (OH) 4 2– ZnO + 2OH - + H 2 O.

It is quite obvious that zinc air cells do not fall under the classification of chemical fuel cells: firstly, they use a consumable electrode (anode), and secondly, the fuel is initially placed inside the cell, and is not supplied during operation from the outside.

The voltage between the electrodes of one zinc air cell is 1.45 V, which is very close to that of alkaline (alkaline) batteries. If necessary, to obtain a higher supply voltage, several cells connected in series can be combined into a battery.

Zinc is a fairly common and inexpensive material, due to which, when deploying mass production of zinc air cells, manufacturers will not experience problems with raw materials. In addition, even at the initial stage, the cost of such power supplies will be quite competitive.

It is also important that zinc air cells are very environmentally friendly products. The materials used for their production do not pollute the environment and can be reused after recycling. The reaction products of zinc-air elements (water and zinc oxide) are also absolutely safe for humans and the environment - zinc oxide is even used as the main component of baby powder.

Among the operational properties of zinc-air cells, it is worth noting such advantages as a low self-discharge rate in an unactivated state and a small change in the voltage value during discharge (flat discharge curve).

A certain disadvantage of zinc-air cells is the influence of the relative humidity of the incoming air on the characteristics of the element. For example, a zinc air cell designed to operate at 60% RH will decrease its service life by about 15% as the humidity rises to 90%.

From batteries to rechargeable batteries

Disposable batteries are the easiest zinc air cell option to implement. When creating zinc-air cells of large size and power (for example, intended for powering power plants of vehicles), zinc anode cassettes can be made replaceable. In this case, to renew the energy supply, it is enough to remove the cassette with the spent electrodes and install a new one instead. Used electrodes can be recovered for reuse electrochemically at specialized enterprises.

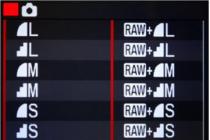

If we talk about compact batteries suitable for use in portable PCs and electronic devices, then the practical implementation of the option with replaceable zinc anode cassettes is impossible due to the small size of the batteries. This is why most of the compact zinc air cells currently on the market are disposable. Small size single-use zinc-air batteries are produced by Duracell, Eveready, Varta, Matsushita, GP, as well as the domestic company Energia. The main area of application of such power sources is hearing aids, portable radios, photographic equipment, etc.

Many companies now make disposable zinc air batteries

Several years ago, AER produced Power Slice zinc-air batteries for laptop computers. These items were designed for Hewlett-Packard's Omnibook 600 and Omnibook 800 series notebooks; their battery life ranged from 8 to 12 hours.

In principle, there is also the possibility of creating rechargeable zinc-air cells (batteries), in which, when an external current source is connected, the zinc reduction reaction will take place at the anode. However, the practical implementation of such projects has long been hampered by serious problems associated with the chemical properties of zinc. Zinc oxide dissolves well in an alkaline electrolyte and in dissolved form is distributed throughout the electrolyte volume, moving away from the anode. Because of this, when charging from an external current source, the geometry of the anode changes significantly: zinc oxide recovered from oxide is deposited on the surface of the anode in the form of ribbon crystals (dendrites), similar in shape to long spikes. Dendrites pierce the separators, causing a short circuit inside the battery.

This problem is aggravated by the fact that in order to increase the power, the anodes of the zinc-air cells are made of crushed powdered zinc (this allows to significantly increase the surface area of the electrode). Thus, as the number of charge-discharge cycles increases, the surface area of the anode will gradually decrease, adversely affecting cell performance.

To date, Zinc Matrix Power (ZMP) has achieved the greatest success in compact zinc air batteries. ZMP specialists have developed a unique Zinc Matrix technology, which has solved the main problems arising in the process of battery charging. The essence of this technology is the use of a polymer binder, which ensures the unhindered penetration of hydroxide ions, but at the same time blocks the movement of zinc oxide dissolving in the electrolyte. By using this solution, it is possible to avoid noticeable changes in the shape and surface area of the anode for at least 100 charge-discharge cycles.

The advantages of zinc-air batteries are long operating time and high specific energy consumption, at least twice as high as those of the best lithium-ion batteries. The specific energy consumption of zinc-air batteries reaches 240 Wh per 1 kg of weight, and the maximum power is 5000 W / kg.

According to the ZMP developers, today it is possible to create zinc-air batteries for portable electronic devices (mobile phones, digital players, etc.) with an energy capacity of about 20 Wh. The smallest possible thickness of such power supplies is only 3 mm. Experimental prototypes of zinc-air batteries for notebooks have an energy capacity of 100 to 200 Wh.

Zinc Air Prototype Battery by Zinc Matrix Power

Another important advantage of zinc air batteries is the complete absence of the so-called memory effect. Unlike other types of batteries, zinc air cells can be recharged at any charge level without compromising their energy capacity. In addition, zinc air cells are much safer than lithium batteries.

In conclusion, one cannot fail to mention one important event that became a symbolic starting point for the commercialization of zinc air cells: on June 9 of last year, Zinc Matrix Power officially announced the signing of a strategic agreement with Intel Corporation. Subject to the terms of this agreement, ZMP and Intel will join forces to develop a new laptop battery technology. Among the main goals of these works is to increase the battery life of laptops up to 10 hours. According to the existing plan, the first models of notebooks equipped with zinc-air batteries should go on sale in 2006.

These elements are distinguished by the highest density of all modern technologies. This is due to the components used in these batteries. Atmospheric oxygen is used as a cathode reagent in these elements, which is reflected in their name. In order for the air to react with the zinc anode, small holes are made in the battery case. Potassium hydroxide, which has high conductivity, is used as an electrolyte in these cells.

Originally designed as non-rechargeable power supplies, zinc-air cells are characterized by a long and stable shelf life, at least if kept airtight, in an inactive state. In this case, over a year of storage, such elements lose about 2 percent of their capacity. Once air enters the battery, these batteries last no longer than a month, regardless of whether you use them or not.

Several manufacturers have started using the same technology in rechargeable cells. Best of all, such elements have proven themselves during long-term operation in low-power devices. The main disadvantage of these elements is their high internal resistance, which means that in order to achieve high power, they must be huge in size. This means the need to create additional battery compartments in laptops, comparable in size to the computer itself.

But it should be noted that they began to receive such application quite recently. The first such product is a joint creation of Hewlett-Packard Co. and AER Energy Resources Inc. - PowerSlice XL - showed the imperfection of this technology when used in laptop computers. This battery, designed for the HP OmniBook 600 notebook, weighed 3.3 kg - more than the computer itself. She provided work for only 12 hours. Energizer has also adopted this technology in its small button batteries used in hearing aids.

Recharging batteries is also not easy. Chemical processes are very sensitive to the electric current supplied to the battery. If the applied voltage is too low, the battery will supply current, not accept. If the voltage is too high, unwanted reactions can begin that can damage the cell. For example, when the voltage rises, the current strength will certainly increase, as a result, the battery will overheat. And if you continue to charge the cell after it has been fully charged, explosive gases can begin to evolve in it and even an explosion can occur.

Charging technologies

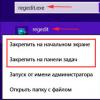

Modern charging devices are rather sophisticated electronic devices with various degrees of protection - both for yours and for your batteries. In most cases, each cell type has its own charger. Incorrect use of the charger can damage not only the batteries, but the device itself, or even battery-powered systems.

There are two operating modes for chargers - constant voltage and constant current.

The simplest are constant voltage devices. They always produce the same voltage and supply current depending on the battery level (and other environmental factors). As the battery charges, its voltage increases, so the difference between the charger and battery potentials decreases. As a result, less current flows through the circuit.

All that is needed for such a device is a transformer (to reduce the charging voltage to the level required by the battery) and a rectifier (to rectify AC to DC used to charge the battery). These simple chargers are used to charge car and ship batteries.

As a rule, lead-acid batteries for uninterruptible power supplies are charged with similar devices. In addition, constant voltage devices are also used to recharge lithium-ion cells. Only there are added circuits to protect batteries and their owners.

The second type of chargers provides constant amperage and changes the voltage to provide the required amount of current. As soon as the voltage reaches the full charge level, charging stops. (Remember, the voltage generated by the cell drops as it discharges.) Usually such devices charge nickel-cadmium and nickel-metal hydride cells.

In addition to the required voltage level, chargers need to know how long it takes to recharge the cell. The battery can be damaged if it is charged for too long. Several technologies are used to determine the recharge time, depending on the type of battery and the "intelligence" of the charger.

In the simplest cases, the voltage generated by the battery is used for this. The charger monitors the battery voltage and turns off the moment the battery voltage reaches the threshold level. But this technology is not suitable for all elements. For example, it is not acceptable for nickel-cadmium. In these elements, the discharge curve is close to a straight line, and it can be very difficult to determine the level of the threshold voltage.

More "sophisticated" chargers determine the recharge time based on temperature. That is, the device monitors the temperature of the cell, and turns off, or reduces the charge current when the battery starts to heat up (which means overcharge). Typically, thermometers are built into such batteries, which monitor the temperature of the cell and transmit an appropriate signal to the charger.

Smart devices use both of these methods. They can switch from a high charge current to a low one, or they can maintain a constant current using special voltage and temperature sensors.

Standard chargers provide less charge current than cell discharge current. And chargers with a higher current value provide a higher current than the nominal discharge current of the battery. Trickle charging devices use such a small current that it only prevents the battery from self-discharging (by definition, such devices are used to compensate for self-discharge). Typically, the charge current in such devices is one twentieth, or one thirtieth of the nominal discharge current of the battery. Modern chargers can often operate at multiple charge currents. They use higher currents at first and gradually switch to lower currents as they approach a full charge. If a battery is used that can withstand low-current charging (nickel-cadmium, for example, cannot withstand), then at the end of the charging cycle, the device will switch to this mode. Most chargers for laptops and cell phones are designed so that they can be permanently connected to the cells and not harm them.

In the fifth issue of our magazine, we told how to make a gas accumulator ourselves, and in the sixth - a lead-potash accumulator. We offer our readers another type of power source - a zinc air cell. This cell does not require charging during operation, which is a very important advantage over batteries.

The zinc-air cell is now the most advanced current source, as it has a relatively high specific energy (110-180 Wh / kg), is easy to manufacture and operate, and is most promising in terms of increasing its specific characteristics. The theoretically calculated power density of the zinc air cell can be up to 880 Wh / kg. If at least half of this power is reached, the element will become a very serious competitor to the internal combustion engine.

A very important advantage of the zinc air cell is

small change in voltage under load as it is discharged. In addition, such an element has significant strength, since its vessel can be made of steel.

The principle of operation of zinc air cells is based on the use of an electrochemical system: zinc - caustic potassium solution - activated carbon, which adsorbs atmospheric oxygen. Choosing the composition of the electrolyte, the active mass of the electrodes and choosing the optimal design of the cell, it is possible to significantly increase its specific power.

Miniature zinc air batteries (galvanic "tablets") with a nominal voltage of 1.4V are used for reliable and uninterrupted operation of analog and digital hearing aids, sound amplifiers and cochlear implants. High environmental friendliness of micro batteries and the inability to leak ensure complete safety of consumers. Our online store offers you to buy at affordable prices the widest range of high-quality batteries for hearing aids of in-ear, in-the-ear and behind-the-ear types.

Benefits of hearing aid batteries

The zinc air battery housing contains a zinc anode, an air electrode and an electrolyte. The catalyst for the oxidation reaction and the formation of an electric current is atmospheric oxygen supplied through a special membrane in the housing. This battery configuration provides a number of operational benefits:

- compactness and light weight;

- ease of storage and use;

- uniform charge return;

- low self-discharge (from 2% per year);

- long service life.

So that you can timely replace worn-out batteries with new ones in devices of low, medium and strong power, we sell batteries for hearing aids in St. Petersburg in convenient packages of 4, 6 or 8 pcs.

How to buy hearing aid batteries correctly

On our website, you can always buy retail and wholesale batteries for hearing enhancers from renowned manufacturers Renata, GP, Energizer, Camelion. To correctly select the size of the battery, use our table, focusing on the color of the protective film and the type of device.

Attention! After removing the colored sealing sticker, wait a few minutes and only then insert the "tablet" into the device. This time is necessary to allow sufficient oxygen to enter the battery and reach its full capacity.Our prices are lower than our competitors because we buy directly from the manufacturer.

Long time scope zinc air batteries did not go beyond medicine. Their high capacity and long (inactive) lifespan have allowed them to seamlessly occupy the niche of disposable hearing aid batteries. But in recent years, there has been a great increase in interest in this technology from automakers. Some believe that an alternative to lithium has been found. Is it so?

A zinc-air battery for an electric vehicle can be arranged as follows: electrodes are inserted into a compartment divided into compartments, on which air oxygen is adsorbed and reduced, as well as special removable cassettes filled with anode consumable material, in this case, zinc granules. A separator is placed between the negative and positive electrodes. An aqueous solution of potassium hydroxide or a solution of zinc chloride can be used as an electrolyte.

The air entering from the outside with the help of catalysts forms hydroxyl ions in the aqueous electrolyte solution, which oxidize the zinc electrode. During this reaction, electrons are released, forming an electric current.

Advantages

According to some estimates, world reserves of zinc are about 1.9 gigatons. If we start the world production of zinc metal now, then in a couple of years it will be possible to assemble a billion zinc-air batteries with a capacity of 10 kW * h each. For example, it will take more than 180 years to create the same amount under current lithium mining conditions. The availability of zinc will also reduce the price of batteries.

It is also very important that zinc air cells, having a transparent recycling scheme for waste zinc, are environmentally friendly products. The materials used here do not pollute the environment and can be recycled. The reaction product of zinc air cells (zinc oxide) is also absolutely safe for humans and their environment. It is not for nothing that zinc oxide is used as the main component for baby powder.

The main advantage, thanks to which electric vehicle manufacturers look at this technology with hope, is the high energy density (2-3 times higher than that of li-ion). Already, the energy consumption of Zinc-Air reaches 450 W * h / kg, but the theoretical density can be 1350 W * h / kg!

disadvantages

Since we do not drive electric vehicles with zinc air batteries, then there are also disadvantages. First, it is difficult to make such cells rechargeable with a sufficient number of discharge / charge cycles. During the operation of the zinc air battery, the electrolyte simply dries out, or penetrates too deep into the pores of the air electrode. And since the deposited zinc is distributed unevenly, forming a branched structure, short circuits often occur between the electrodes.

Scientists are trying to find a way out. The American company ZAI solved this problem by simply replacing the electrolyte and adding fresh zinc cartridges. Naturally, this will require a developed infrastructure of filling stations, where the oxidized active material in the anode cassette will be replaced with fresh zinc.

And although the economic component of the project has not yet been worked out, the manufacturers claim that the cost of such "charging" will be significantly lower than refueling a car with an internal combustion engine. In addition, the process of changing the active material will take no more than 10 minutes. Even superfast ones will be able to replenish only 50% of their potential during the same time. Last year, Korean company Leo Motors already demonstrated ZAI zinc air batteries on its electric truck.

ReVolt, a Swiss technology firm, is working on improving the Zinc-Air battery. She proposed special gelling and astringent additives that control the moisture and shape of the zinc electrode, as well as new catalysts that significantly improve the performance of the elements.

Yet the engineers of both companies did not manage to overcome the milestone of 200 Zinc-Air discharge / charge cycles. Therefore, it is too early to speak of zinc air cells as electric vehicle batteries.