12.09.2011

In an analytical balance, in the international classification, the ratio of the maximum load to the division price (resolution) exceeds 100,000, while the maximum weighing value on such equipment cannot exceed 50 kg.

In the domestic classification, there is no, as such, the concept of "analytical balance". There is equipment of analytical accuracy class. This class includes laboratory, jewelry, and technical scales. Although, the classification given by us is also rather arbitrary and is not officially recognized.

Laboratory scales can be of two accuracy classes - special (graduation from 0.1 μg) and the highest (graduation 0.001-0.05 mg). It should be noted that laboratories also have weighing equipment of average accuracy class, to which we, within the framework of this classification, refer to the "technical" class of this equipment.

Jewelry scales have a special and high accuracy class. They are designed for weighing precious metals and stones.

Technical weighing equipment belongs to the middle class of accuracy. The division price in them is 10 mg and higher. They are used in production shops, warehouses, and where a very high accuracy class is not needed.

Analytical group balances can be either mechanical or electronic. Recently, both regulatory requirements and the requirements of the time oblige users to "switch" to electronic measuring devices. So, for example, the regulatory requirements for pawnshops ascribe the obligatory use in the activity of a certain type of instrumentation - I, II, accuracy classes, preferably electronic.

Laboratory work No. 2

Theme: Study of the analytical balance device. Learning weighing rules.

Target: to learn how to analyze the device of an analytical balance, to weigh on them.

Equipment and materials: analytical balance, technical balance, sets of weights, dry salt NaCl, weighing bottles.

General Provisions

And the method of doing the work

Study the device of technical scales, the rules of work on them

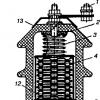

Some laboratory work requires weighing reagents with an accuracy of 0.01 g. This requirement is met technical scales (fig. 1).

The main part of the scale is the rack. 1 with a yoke 2 and weighing cups 8. There are three triangular prisms on the rocker 3. To prevent wear of the prisms, there is a locking device (locking device) 9, relieving them from the load when inoperative.

The balance rack is installed in a strictly vertical position. This is done with set screws. 10, control is carried out on a plumb line 5.

Adjusting screws 4 serve to balance the balance so that the arrow 6 was against the zero division of the scale 7 or deviated from the zero division equally in both directions.

In addition to technical scales in the laboratory, you can use hand (pharmacy) scales. For accurate weighing use analytical balance.

The laboratory technician sets and balances the scales. After installation, do not move or carry the balance to another place. On the right side of the balance, there must be a set of weights and tweezers.

Rice. 1. Technical scales:

1 - rack; 2 - rocker; 3 - prisms; 4 - adjusting screws;

5 - plumb line; 6 - arrow; 7 - scale; 8 - cups; 9 - arresting device; 10 - set screws

A set of weights contains weights of 100, 50, 20, 10, 5, 2, 1 g and plates of 500, 200, 100, 50, 20, 10 mg. Using this set, you can make any mass from 0.01 to 211.1 g. Tweezers are used to take weights.

Weighing rules on technical scales:

1. Check the balance is working properly. To do this, smoothly open the lock and observe the swing of the arrow. If the deviations in both directions from zero are the same, then the balance is considered to be in good order.

2. Objects and weights should be placed in the middle of the cups and only in the locked position of the scales.

3. Place the object to be weighed on the left pan. Weigh chemical reagents in buxes , on watch glass or in test tubes ... The container must first be weighed or balanced with a fraction. Do not place hot, dirty or wet objects on the weighing pan.

4. Weights must be placed on the right pan in a specific order. Start with large weights and gradually move down to lower weights until equilibrium is achieved.

5. Weights should only be taken with tweezers. It is forbidden to put weights on the table and on the weighing pan with the object to be weighed. Do not allow reagents to come into contact with weights. At the end of weighing, record the price of all weights put on the scales.

6. Put the scales in order. Remove everything from the scales, put the weights in their nests.

7. Check the operation of the scales and lock them.

Study the structure of an analytical balance, the rules for working on them

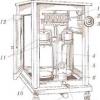

Analytical damper scales ADV-200. They have a maximum permissible load of 200 g (Fig. 2). The scales are mounted on a base plate 10 and housed in a case to protect against dust and air vibrations.

The base board is supported by two set screws 7, with the help of which it is set in a horizontal position, checked against a ball level. The balance is equipped with dampers to speed up weighing. 11 and a special device for removing and applying small weights without opening the door 12. Dampers are devices that reduce the time it takes to calm the rocker arm.

To reduce the wear of the working parts, the scales are equipped with arrester 9, that is, a device that allows you to raise the balance beam and remove the load from the prisms. The balance should always be locked when not in operation. Place on cups 6 scales or remove the object and the weights from them only by pre-locking the scales.

Rice. 2. General view of the analytical balance ADV-200: 1 - a system of levers; 2 - small limb; 3 - large limb; 4 - arrow of the scales; 5 - light screen; 6 - weighing cups; 7 - set screws; 5 - an adjusting screw; 9 - cage; 10 - base board; 11 - dampers; 12 - left door.

For ease of reading, the scales are equipped with an optical device with a light screen 5 (whitograph), which shows an enlarged image of a microscale attached to the arrow of the balance 4. The microscale to the right and left of zero is divided into 10 large divisions, which are numbered to the right from +1 to +10, and to the left from -1 to -10. Each major division is divided into 10 minor divisions. The balance is adjusted so that when one 10 mg plate is loaded, the arrow will deviate from zero by exactly 10 divisions. Thus, the price of one small division is equal to 0.1 mg, or 0.0001 g. A horizontal bar is fixed on the right earring, on which with the help of a system of levers 1 small weights weighing from 10 to 990 mg are hung. The levers are controlled by turning two dials 2 and 3. The large (outer) limb is marked with divisions from 0 to 9, corresponding to 0, 100, 200 and up to 900 mg. On the small (internal) limb, tens of milligrams (mg) are indicated - 0, 10, 20, etc. up to 90 mg. The scales are also supplied with a set of weights weighing from 1 to 100 g.

Rules for working on an analytical balance:

Before starting weighing, it must be remembered that an analytical balance is one of the most accurate and important measuring instruments in a quantitative analysis laboratory. They must be handled carefully and carefully. Below are the basic rules that must be well understood and must be followed when working with analytical balances.

1. Before each weighing, check the balance. Clean the dust carefully, check the zero point.

2. If the balance is found to be faulty, under no circumstances should the balance be repaired by yourself.

3. Do not allow any contact with the uncaged balance. Lower and raise the lock with a careful and smooth turn of the handle.

4. Do not move the balance from the occupied place.

5. Do not overload the balance in excess of the maximum load (in most cases 200 g).

7. Add or subtract the substance to be weighed only outside the weighing case.

8. Do not weigh hot or too cold items. The objects to be weighed must be at the same temperature as the weighing room.

9. All weighings of this analysis are carried out on the same balance, using the same weight.

10. At the end of weighing, make sure that the balance is locked, the load is removed, the case doors are completely closed.

Weighing technique on damper scales:

When weighing on a damper balance, the following rules must be observed:

1. Connect the illuminator to the lighting network using a cord with a plug.

2.Adjust the position of the zero point; for this, without opening the cabinet doors, carefully turn the locking disc until it stops. An automatically illuminated light bulb illuminates an enlarged microscale image on the whitograph screen. When the arrow vibrates, the microscale image moves along the screen, but thanks to the dampers, the arrow stops very quickly. If the balance is not loaded, the zero of the scale must exactly match the vertical line on the screen. This coincidence is achieved by rotating the adjusting screw in one direction or another, which is located outside above the locking disc.

3.The item to be weighed is placed on the left pan of the balance, and weights from the box, the mass of which is an integer number of grams, are placed on the right pan.

4.Close the cabinet door. To determine tenths of a gram using an external disk, weights of 500 are sequentially hung; 200; 100 mg. Notice in which direction the balance arrow deviates. After each turn of the disc, i.e. when removing or imposing any weights, it is necessary to lock the scales. Weights in hundredths of a gram are set using an internal disc.

5. The thousandths and ten-thousandths of a gram are counted on a microscale. To do this, you need to turn the locking disc to failure and, after the arrow stops vibrating, make a reading of the position of the vertical line on the screen scale. Large divisions of this scale correspond to thousandths, and small divisions - to ten-thousandths of a gram. There are plus or minus signs in front of the numbers on the scale. The "plus" sign indicates that the result of the readout must be added to the mass of the balance weights placed on the scales; the minus sign indicates that this result must be subtracted.

For example, if the weight of the weight on the balance is 18.64 g, and the reading on the screen is 5.7 mg, i.e. 0.0057 g, then in the case of a positive reading value, the weight of the item to be weighed is 18.6457 g; if the reading is negative, the mass is:

18.64 - 0.0057 = 18.6343 g.

6. After the end of weighing, record the result obtained, remove the weighed object and weights from the balance.

Laboratory analytical balance

Analytical balances are high-precision laboratory balances and are used in scientific and industrial laboratories of various industries to determine the mass of solid, bulk and liquid substances with an accuracy of 0.1 mg. Semi-microbalances are even more accurate - their readout resolution is 10 μg (0.01 mg). Laboratory analytical balances in accordance with GOST 24104-01 have a special (I) accuracy class. An important characteristic of any balance is the LEL (maximum weighing limit), the LEL value for an analytical balance is in the range from 50 g to 500 g.

The operation of modern electronic analytical balances is based on the principle of electromagnetic compensation. According to this principle, the weight of the load is compensated by an electromagnetic force directed opposite to the weight. The compensating force is determined by the strength of the current flowing in the magnetic coil. The electrical signal from the sensor is converted into digital, corresponding to the measured mass, and displayed on the display.

The analytical balance platform is located inside a transparent display case, which serves to eliminate the accumulation of dust and the influence of air currents on the measurement accuracy. The calibration of this precision instrument can be external (external weight), internal or automatic. The calibration procedure for various models of laboratory analytical balances can be performed in three different ways: by pressing the calibration key; automatically when the ambient temperature changes (adaptive calibration); automatically at predetermined times. Electronic analytical balances are equipped with a large number of additional functions: the choice of a unit of measure of mass (some models have up to 24 units of mass), a tare function (zeroing the tare weight in the entire weighing range), dynamic weighing (weighing animals or non-static objects), percentage weighing (making measurements percentage of components), prescription weighing (weighing a multicomponent mixture), hydrostatic weighing (determining the density of substances), the ability to connect to a PC, etc.

An analytical and semi-analytical balance is a type of balance designed to measure mass with high accuracy.

The maximum load for such scales is from 54 to 520 g, their discreteness is from 0.005 to 0.1 mg. An analytical balance is very sensitive and needs to be protected from air currents by a shield or shroud.

METTLER TOLEDO XPR and XSR analytical balances are equipped with weighing pan SmartGrid which is insensitive to turbulent air currents. This shortens the stabilization time and results in faster results.

Where are analytical balances used? What is this scale used for?

An analytical balance, often referred to as a laboratory balance, is designed for the quantitative analysis of samples. With the help of electronic analytical balances, the following are usually performed:

- preparation of samples and standards;

- weighing according to recipes;

- differential weighing;

- determination of density;

- interval weighing;

- periodic check of pipettes.

How to weigh on an analytical balance?

First, open the door and place the container on the weighing pan using gloves or tweezers. Close the door and wait for the reading to stabilize. Record the weight value. Reset the reading by pressing the Tare button so that the display shows 0.0000 g. Place the amount of sample corresponding to the target weight on the weighing pan. Close the door again and wait for the reading to stabilize. Record the net weight value. Scales that have been switched off for cleaning should be warmed up before use.

METTLER TOLEDO analytical balances are easy to clean. The protective cover can be disassembled in a few seconds, and its panels can be washed in the dishwasher. Cleaning and Operating Procedure Recommendations

What is the uncertainty of weighing on an analytical balance?

Uncertainty is present in any measurement process. Determining its limits is an important part of any measurement. This requires an assessment of the performance of the balance, the properties of the object to be weighed and the environmental parameters. Uncertainty estimation is an integral part of the calibration procedure.

Why Calibrate an Analytical Balance?

Calibration ensures your balance is accurate and meets standards such as ISO, GLP / GMP, IFS and BRC. Documented calibration procedures indicate the quality of the measurements and should be performed regularly throughout the life of the balance.

Balance calibration should not be confused with adjustment; calibration must be performed after every adjustment or repair.

How do I calibrate?

The calibration of the analytical balance is carried out by the service technician according to the standard procedure using special software. There are several steps to be followed:

- Determine how well an instrument is performing by checking the consistency between measurement standards and readings by calibration.

- Check if the device meets the specified requirements using the criteria for conformity and non-conformity.

- If a discrepancy is found, adjust the device so that the deviations do not exceed the permissible limits.

- Repeat the calibration to confirm that the tolerances are correct.

In between calibrations, the user should perform periodic tests to identify potential problems.

METTLER TOLEDO has developed a scientific standard for the correct selection, calibration and operation of weighing equipment. This global standard is called GWP®, or Good Weighing Practice ™.

What are the tolerances when calibrating the balance?

Tolerances determine whether the balance is “good enough” to meet specific process requirements. Tolerances establish criteria for assessing conformity or non-conformity. Tolerance values are determined from various sources:

- Normative tolerances

Listed in OIML R76 or NIST Handbook 44 (US only) governs commercial equipment requirements. These are tolerances that are flexible enough to be met easily using laboratory balances or weighing processes at the lower end of the measuring range. - Manufacturer approvals

Control the compliance of the equipment with the manufacturer's requirements. These tolerances do not take into account the requirements of a specific production process and are therefore not suitable for optimizing weighing. - Technological tolerances

User definable, help optimize processes and save materials, reduce the risk of rejects and the need to recycle products. For balances certified for trading, these tolerances must be applied in conjunction with the regulatory tolerances.

Regulatory tolerances protect consumers, but do not take into account specific manufacturer requirements. Optimizing process tolerances that apply to instrumentation can significantly increase process profitability.

What is the minimum weight for an analytical balance?

Each analytical balance has a specific minimum weight, depending on the parameters of the load cell, its location and environmental conditions. The minimum weight is the accuracy limit of the instrument. Below this value, the relative measurement uncertainty (the absolute measurement uncertainty divided by the load is usually indicated as a percentage) exceeds the permissible weighing error, and the result cannot be reliable.

To find the value of the minimum weight, it is necessary to estimate the measurement uncertainty on this device under specific conditions. You can also assess reproducibility - a major source of error when weighing small samples - with a small weight that does not exceed 5% of the maximum load capacity.

When analytical balance METTLER TOLEDO installed by a certified specialist, the minimum sample weight is monitored by a special MinWeigh function. If the weight of the sample is less than a certain value, the instrument display will turn red.

Accuracy and precision of analytical balances - how to evaluate them and what is the difference between them?

Precision refers to the closeness between readings obtained from repeated measurements for the same object. Accuracy means the closeness of the measured value to the true value of the measured value. It depends on the discreteness of the balance, reproducibility, linearity and angular error. Accuracy can be determined:

- using an external reference weight of known mass (traceable calibrated weight);

- by automatic internal calibration of the balance using the built-in reference weight;

- the accuracy of the balance should be determined only at the place of use.

How does static electricity affect analytical balances and how can electrostatic charges be eliminated?

Instability caused by electrostatic charges impairs the reproducibility of weighing results. Static electricity creates forces on the weighing pan and distorts analytical weighing results. Precautions to reduce these effects:

- maintain sufficient air humidity (≥ 45 ... 50%);

- if possible, use antistatic containers (preferably metal);

- avoid friction of containers against each other;

- When working with small samples, use a metal dish with a raised edge to shield them from electrical fields.

For more reliable removal of electrostatic charge, samples and containers should be treated with an ionizer before weighing on an analytical balance.

More details about electrostatic charges and their physical properties.

Purpose of the laboratory balance- determination of the mass of objects and liquid or bulk substances. Depending on where these devices are used, certain requirements are imposed on them. For weighing products in stores and supermarkets, a certain error in the readings is allowed, but in jewelry workshops, pharmacology and testing laboratories, measuring instruments with a high accuracy class are used.

Describing laboratory scales, it should be noted right away that these are universal devices that are used for various preparative and analytical studies. Mechanical scales are a thing of the past long ago, giving way to electromechanical or electronic instruments.

Modern electronic devices are very accurate and practical; they do not require the use of additional bulky mechanical weights and other parts. Laboratory balance device complex in technical terms, at the same time the devices are easy to use. They are equipped with electrical sensors that transmit information about the weight of the weighed objects or substances to an informative display.

To all laboratory balances have general technical requirements... The characteristics of the devices must meet certain requirements of GOST and the regulations of the protocol of the Council for Metrology, Standardization and Certification.

Laboratory balance classification

Depending on the area of application and accuracy class, classified into the following types:

- Analytical balance. This equipment meets the 1-2 class of accuracy and determines the mass of objects with an accuracy of 5 decimal places, and the error of such devices does not exceed 0.0002 g.

- Laboratory scale class 3.4. These devices determine the mass to the third decimal place.

- Technical scales corresponding to the average accuracy class. They allow you to weigh samples with an accuracy of 1/10 g.

Depending on the accuracy class and are determined with what laboratory scales pick up for one purpose or another.

What is weighed on a laboratory balance?

Modern electronic laboratory balance are used for weighing goods weighing 10 mg or more. They are used in pharmacology and medicine for precise dosage of drugs. These measuring instruments are widely used in the food and chemical industries.  Minimum laboratory balance error allows you to use them where you need to accurately determine the mass of objects or determine the weight of samples.

Minimum laboratory balance error allows you to use them where you need to accurately determine the mass of objects or determine the weight of samples.

Various classes precision determine their purpose. The higher the equipment is classified, the more accurate the indicators.

How to choose?

I think about it how to choose, the following factors should be considered:

- the largest measuring limit of the balance. It is determined by the maximum mass of the container and sample to be weighed.

- calibration using an integrated weight. This process is automatically triggered by a signal from a temperature sensor built into the measuring device.

- functional characteristics and should allow solving, when weighing, non-standard tasks (to determine the weight of containers of complex shape, filters, to neutralize statistical charges, to calibrate pipettes, etc.).

Together with the laboratory balance must be accompanied by an operating manual, which describes in detail: how to determine the zero point what is the NmLV (minimum weighing limit) of the device, the corresponding calibration mechanism and other information about the characteristics and capabilities of the equipment.