Consider repairing a floor fan with your own hands, using the example of a typical product from the Krasnodar plant. There is nothing complicated inside, but it is not easy to immediately describe the method of adjusting the rotation speed. The construction is mediocre. A relatively heavy body tramples on a weightless leg, sensing the slightest push, the product falls. The situation is aggravated by lying carpets. Four plastic supports scattered around the corners of the thinnest steel crosses do not save. The stand is fragile, bends easily, rests on snot. Therefore, the first recommendation is not to mess with products that have mechanical instability, so as not to get psychic. Bork products are equipped with fall protection, but not the products of the Krasnodar plant. However, the motor will not burn out in case of excess, there is protection ...

The device of a typical floor fan

Do-it-yourself floor fan repair is on the agenda! You should start small: the simplest fans do not have a ground terminal. The device does not have a degree of electrical safety. The floor fan device includes a housing made of plastic. Water will get inside - expect a good shake. The floor fan of this type must not be used near water. Starting with an aquarium with fish, ending with a flower vase. It is especially dangerous where small children live. The contraption will fall, the child will guess to pour milk inside ... Draw your own conclusions:

- the design is unstable;

- the base breaks easily, bends;

- there is no protection against electric shock.

If the floor fan falls, there is a high probability that nothing will happen. Let's dive into the structure. Let's leave aside the features of controlling the speed of the engine and the buttons for now. Let's talk about the gearbox. The Krasnodar floor fan carries one asynchronous capacitor motor. The front side of the shaft through the pin, the nut with the left thread is connected to the blades, the rear goes to the gearbox formed by two gears, one is double.

The shaft is threaded, catching, rotating, the teeth of the large wheel. The torque is transferred to a small wheel that drives the flywheel. The gear of the crank mechanism is a hand in diameter, so the rotation is inferior to the speed of the original shaft of the induction motor.

- The blades rotate at full motor speed.

- The crank mechanism, thanks to the gearbox, moves more slowly.

Through the driveline, the crank is hooked to the leg, the engine housing is mounted on the axle. When the shaft of an asynchronous motor rotates, the blades move smoothly in one direction or the other. However, you can stop the process. For a double gear, the roll is attached to the larger gear with two balls with a spring inserted into the through hole. If you pull the adjuster knob directly connected to the axle, the latch slides up. The connection between the gear, the shaft is lost, the rotation stops. The mechanism implements fall protection: six grooves are cut along the internal mounting hole of the drive gear. Balls fit. There are six positions, the mutual transition is accompanied by a click, the axis rotates relative to the gear, the balls hit the walls, sliding into the grooves.

Clicks are heard, the floor fan has fallen down. The drive jammed, works, clicking, the protective mechanism, saving the motor from combustion.

We believe that the mode is unfavorable for the floor fan, do not turn off the device, the motor thermal fuse will certainly break. The gearbox is mounted with three bolts to the engine, cut through with a pair of lubrication holes through which plastic gears can be flavored. Refers to the drive, rotating at the speed of an asynchronous motor.

Headache, how to fix a floor fan and assemble. We see the alignment: the relative position of the gearbox is incorrectly set, the legs through the gear, the floor fan head will move asymmetrically relative to the frontal plane. May be annoying. Connect the gearbox, test the product by connecting the power. Be careful not to get electrocuted, try to visually determine the correctness of the assembly.

Floor fan motor

Inside the fan there is an asynchronous motor with regulation of the speed of rotation of the shaft by switching the windings. A capacitor is attached to the gearbox. The radio element is not starting. We believe that it is not without reason that the windings are fastened four in two rows, shifted relative to each other by an eighth of a turn. Field rotation uses voltage phase and a 90 degree shift. The moment is useless to the technician, one winding of the asynchronous motor of the floor fan will burn out, the motor will have to be changed. It is not possible for a beginner to wind a complex product on their own.

Speed control is performed by switching the supply voltage to the appropriate wires by switching the buttons on the rack. One core goes from the cord from the socket to the engine, and the position of the second is selected by the operator. Only one of the speeds is pressed at the same time, which is ensured by mechanical methods of blocking the parallel connection. Krasnodar products please with the presence of illumination: the top button ensures the burning of the diode. Will avoid collision in the dark with a floor fan. Indirectly indicates: the manufacturer is aware of the instability of the product.

The engine is made up of an insulated silumin rotor-drum, the wiring of the coils is sealed. The structure remains unknown for obvious reasons, the question is meaningless. We believe that the probability of failure of the rotor is relatively small, the armature receives power from the stator. The structure is usually represented by a squirrel cage. A set of longitudinal conductors arranged in a circle, united by two rings at the ends. An impeller is located on both ends of the rotor, blowing around the stator coils. Allow the asynchronous motor to work harder. The Krasnodar floor fan has plastic impellers.

In case of ambiguity, ring the wiring from the button (without disassembling the fan), investigating a hidden malfunction. The resistance of the working winding is never zero, too high. The break is not hard to guess. The starting winding is called from the capacitor contacts. The direction of rotation is determined by the relative position of the starting and main windings, therefore, by confusing them, you will get the wrong result.

Of course, if at least one winding fails, the engine will not work. One phase is not enough to accelerate the rotor. Rotate the blades in a clockwise direction (with your hand withdrawn) to see if there is a specific problem. The floor fan will work - one winding burned out. It is not correct to talk about starting, working coils, copper coils are identical. Capacitor motor.

Floor Fan Motor Speed Control Method

Nothing is said about the method of regulating the speed, no wonder. In the considered model, four wires come to the coils, one supplies the plug. Three others enter the winding through fabric tubes. What is inside is not known for certain. The choice is small, the induction motor with an insulated rotor is controlled in two ways:

- Change in voltage amplitude.

- Switching of windings with different number of turns.

We do not take inverter control into account, in this case there is simply nowhere to fit such a complex circuit. It remains to regulate the amplitude of the voltage. On each of the wires sits an unequal number of turns. One speed (two) will fail, the tubes will have to be cut, therefore, the electrical circuit of the engine will become obvious. An assiduous master will wind a new coil, a lazy one will take money from the client to buy a new engine (the old one will be used for non-ferrous metal).

Indirectly, the number of turns is known through the ratio of resistances between the outputs of each speed. The tester uses a DC voltage to measure the magnitude, so the inductive part of the impedance is dropped from consideration. The number of turns is directly proportional to the ohmic resistance of the winding section.

How to disassemble a floor fan

From what has been said, it is clear: there is nothing to break inside the floor fan. This is a motor and a capacitor. The rest falls on the mechanical part, the gearbox. If there is whistling or noise, try lubricating the gears. How to do this is clear from what has been said. There are a couple of holes in the gearbox housing for these purposes. Solid oil is suitable for plastic parts.

Self-repair of a floor fan should not cause much difficulty. Replace the motor with one of the correct weight and size. The main types of breakdowns relate to the mechanical part, restoration is carried out by conventional (plastic welding with polyethylene) methods by skillful hands.

Installing a fan in the bathroom is a very good idea. Thanks to him, you can ventilate the room in a matter of minutes. Thanks to the fan installed in the exhaust duct, the draft of the hood itself is enhanced, which is useful when the humidity in the bathroom rises or after a smoke break.

However, over time, especially if people smoke in the bathroom or toilet, the exhaust fan becomes very dirty. As a result, traction weakens. In addition, over time, the lubrication in the motor bearings runs out and the fan starts to work poorly, and may even burn out. Therefore, periodically he should do prophylaxis.

If your fan starts to creak and change the speed due to wedging, do not rush to throw it away, it can still be extended. First, remove the fan. Usually it is mounted on four screws. It is connected to the power supply using a conventional two-wire terminal. It is convenient to connect the fan to the switch so that you can turn it on and off as needed.

And so the fan is very dirty, the engine wedges and overheats, so it needs to be lubricated and cleaned.

Fig.1.

Fig.2.

Fig.3.

And remove the engine, it is mounted on two screws.

Fig.4.

Here is the fan motor itself.

Fig.5.

We let him cool down. Then we clean it with a brush and lubricate it. To lubricate the fan, you need literally two drops of engine oil, you should not pour a lot. One drop is needed for the front bearing, the second for the rear. Next, rotate the rotor (shaft) of the engine by hand so that the lubricant is distributed. It is immediately felt that it has become much better to rotate. Now the engine will not wedge and overheat.

Fig.6.

Now we assemble its fan and install it in place.

Fig.7.

We looked at how easy it is to bring an old fan back to life. In most cases, fan failure is due to contamination and lack of lubrication in the motor bearings. By cleaning and lubricating the motor, you can regularly extend the life of the fan. The whole job takes no more than 10-15 minutes, and saves time and money that could be spent on a new bathroom or kitchen fan.

The normal operation of any computer, and especially a device that is more than three years old, cannot be carried out if the system unit is not cleaned of dust and is not lubricated from time to time. But not all PC users consider this a necessary condition, which is fundamentally wrong. The rather rapid consumption of thermal paste is affected by the heating of internal elements and, as a result, an increase in temperature in the system unit. Changing the lubricant does not require much effort or special skills. The main thing is elementary knowledge and utmost accuracy. Next, the maintenance process will be described and, in fact, it will be told how to disassemble the cooler.

Alarms

Any malfunctions manifest themselves as alarms. So, before disassembling the cooler, it is worth finding out whether it is really necessary. If there are no obvious signs of problems, then this does not mean that nothing is worth doing. Sometimes it is necessary to lubricate components for preventive purposes. But if there are good reasons for this, then decisive action must be taken all the more.

The main sign that difficulties arise in the operation of the system unit is an increased level of emitted noise. A noticeable hum will cut the ear, over time it will only become stronger. But it’s better not to bring it to such a state and change the lubricant in a timely manner, because a new cooler will cost much more.

Start cleaning

The question “how to disassemble the cooler” is easy enough to deal with. The first step is to turn off the computer from the network and disconnect all available cords. The next step is to remove the case cover on the left side, with the unit carefully placed on the right side. Next, you need to clean the inside of the computer from dust and foreign contaminants.

Since the work of the cooler consists in the correct distribution of air flows, then, accordingly, the part takes a lot of dust and small debris from the environment. Most of the unnecessary dust pollution settles on the radiator and other important components.

Cleaning can be started with the most common actions, for example, using a conventional vacuum cleaner. But it’s better to finish more carefully - wipe the parts with a napkin moistened with any alcohol solution. You can use both cologne and vodka. Any alcohol-containing substance is good because it does not react with air, dries quickly and does not cause metal corrosion (which is typical for water). Depending on how finely and deeply the cleaning was carried out, the further operation of the computer also depends.

CPU fan prevention

More details on how to disassemble the cooler can be found below. To carry out this action, you need to remove the processor fan, and then the heatsink. They also need to be separated from each other. The cleaning of these elements also consists of two stages - superficial cleaning with a vacuum cleaner and more detailed cleaning, carried out with a match.

To ensure further trouble-free operation, it is necessary to affect both the surface of the radiator and its fins, as well as related parts.

Replacing thermal paste

The best CPU cooler is one that is well lubricated. When disassembling a computer, it is very important to replace the special thermal paste. To do this, you must first remove the remnants of the old substance. They are washed off with an alcohol solution. After that, be sure to wait for the surface to dry well. At the end, you need to apply a thin, neat layer of new grease.

In the event that there is no new thermal paste, and there is a need to replace it, you should try to evenly distribute traces of the old substance over all rubbing places.

one system

Many are interested not only in how to disassemble an Acer laptop cooler, but also in the reverse action. This is true for those who prefer to apply a lubricant to a single system. In order to do this, you need to find a sticker on the cooler. After removing it, you can carefully clean the fan spindle from traces of grease.

Where the sticker was located, you also need to clean it. It is necessary to wipe this place with an alcohol solution and dry it. The next step is to apply a new paste. After that, you can return the sticker back (the original sticker can be replaced with adhesive tape). Its remains should not disrupt the operation of the part, as they will create excessive noise. If you do this process accurately, then the efficiency will be maximum. The main thing is to ensure tightness, grease should not leak out due to an increase in temperature.

If lubrication is carried out in this way, then the question of how to disassemble a non-separable cooler will not become a problem.

Power Supply Fan Prevention

During the cleaning process, the user is faced with the question of how to disassemble the power supply cooler. First of all, you need to dismantle the component. It is desirable that all manipulations performed with the unit do not require disconnecting the cords from the power consumers. Then everything happens according to the standard scheme - first, general cleaning with a vacuum cleaner, and then more thorough, with the help of an alcohol-containing substance.

To produce a deep and thorough cleansing, you need to rid the unit of the fan. It is necessary to touch all surfaces, radiator fins and fan wings.

Cleaning the power supply fan is carried out in the same way as the processor cooler. It is necessary to separate the sticker from the surface, under it there will be an end cap. This element also needs to be removed. Using an ordinary match, you need to remove dirt in the form of clots of old grease and dust from the fan shaft and washer.

Then you also need to evenly and evenly distribute the oil over the cooler spindle. To do this, the fan is rotated - a few revolutions around the axis are enough.

After completing all the manipulations, the system must be assembled: put the plug in place, glue the adhesive tape. In the process, it is desirable to clean and dry the ends of the fan. The ends of the adhesive tape are removed, and the power supply is mounted back.

It is also important to secure the lid tightly. If it sits loosely, it will create a sound similar to an idle fan.

The quiet operation of the computer is an indicator that everything was not done in vain.

Lubricant selection

When cleaning a PC, the question arises of whether Experts advise choosing not too viscous mixtures as a lubricant. This is due to the fact that the latter lead to a decrease in the speed of revolutions. Engine oil is the best choice. Alternatively, synthetic and mineral oils can be used. Just don't use them at the same time.

A few drops of oil are applied with a match. A match is needed in order to take the minimum amount of substance.

Suitable for fan lubrication:

- WD-40 - anti-corrosion mixture;

- hairdressing tool oil;

- Silicone Grease;

- synthetic motor oil;

- mineral motor oil.

Grease preparation

How to lubricate a computer cooler? You can make the mixture at home. The composition should include graphite and oil. Graphite can be taken from a pencil, it is better to use synthetic oil.

best cooler

Thus, the best CPU cooler is one that is regularly looked after by the user. The part must be cleaned and lubricated in a timely manner. These procedures will ensure reliable and comfortable operation of the fan of almost any model.

As for the specific characteristics of the best cooler, most parts today are manufactured with similar parameters, especially for fans. Of course, there are "gaming" models that provide good cooling, but their use is advisable only with a high load on the processor: demanding games, working with several massive programs at the same time, complex audio or video processing. If we talk about manufacturers, products of such brands as Cooler Master, DeepCool (an excellent choice is the Deepcool Lucifer V2 model), Thermaltake (for example, Thermalright Macho Rev.A), Zalman (for example, the Zalman CNPS12X model) are of high quality.

If the cooler makes creaking sounds while the computer is running, most likely it needs to be cleaned of dust and lubricated (or maybe even replaced). You can lubricate the cooler at home, using improvised means.

First, prepare all the necessary components:

- Alcohol-containing liquid (you can vodka). It will be needed for better cleaning of the cooler elements;

- For lubrication, it is better to use machine oil of a non-viscous consistency. If it is too viscous, the cooler may start to work even worse. It is recommended to use a special oil for lubricating components, which is sold in any computer store;

- Cotton pads and sticks. Just in case, take more of them, because. the recommended amount is highly dependent on the degree of contamination;

- Dry cloth or napkins. It will be ideal if you have special wipes for wiping computer components;

- A vacuum cleaner. Preferably having a small power and / or having the ability to adjust it;

- Thermal paste. Optional, but recommended during this procedure is to change the thermal paste.

At this stage, you need to disconnect the computer from the power supply, if you have a laptop, then also remove the battery. Place the case in a horizontal position in order to reduce the risk of accidentally disconnecting any component from the motherboard. Remove the cover and get to work.

Stage 1: initial cleaning

At this stage, you need to do the highest quality cleaning of all PC components (especially fans and radiator) from dust and rust (if any).

Follow these instructions:

Some components and parts of a computer and laptop need regular maintenance. For example, a fan or, as it is also called, a cooler. It is installed to cool the processor, power supply and video card. On some motherboards, the fan is mounted on the southbridge. If the cooler is not regularly cleaned and lubricated, it will become clogged with dust, and it will start making noise, annoying those around you with a wild roar when turned on, and later - all the time during operation. And this is not "gud". Therefore, I advise you not to take it to the extreme, but to lubricate the fan on the processor and video card in a timely manner. How to do this, I will now clearly show.

Computer fan bearing grease

What can lubricate the cooler? For these purposes, ordinary household machine oil is best suited. Penetrating lubricant WD-40 is also excellent for these purposes:

Also in electronics stores you can find special lubricants for the cooler such as silicone oil or lubricant Ciatim 203 or 221, FIOL. In extreme cases, Litol is also suitable.

What can not use for lubricating computer fans? Firstly, it is vegetable or butter, animal fats, petroleum jelly or liquid paraffin, water-based lubricants, various creams and moisturizers.

What we will smear decided, now let's go directly to the actions.

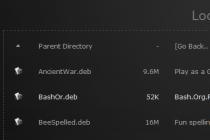

Step 1. Dismantling the cooling system

We start by removing the fan from the processor or video card heatsink. On many models, the CPU coolers can be removed by simply unscrewing 4 screws.

In more complex cases, you will have to remove everything completely, along with the radiator, and then disassemble it. In the case of the video card, everything is the same. On laptops it’s even more difficult - usually you need to disconnect the entire “snail” along with the cooler:

After the dismantling is completed, be sure to wipe the dust from the blades and body with a damp cloth or cloth.

Step 2. Tear off the sticker

Each computer fan has a sticker that blocks access to the locking sleeve. Carefully peel it off so that you can glue it back:

There may also be a plastic or rubber stopper under the sticker:

It also needs to be removed.

Step 3: Lubricate the fan shaft of the processor or video card

At this stage, you need to be careful not to fill everything with grease, drip oil or spray WD-40 on the cooler axis:

By the way, it is most convenient to lubricate the fan with engine oil using a conventional 5 ml syringe - simply and accurately.

After that, return the plug back and glue the sticker back.

How to disassemble the cooler?!

In some cases, when the used valve has not been cleaned for a long time and dusted to the eyeballs so that the blades turn poorly, it is best to completely disassemble it, clean it and anoint it.

To do this, very carefully remove the locking sleeve:

Or a locking rubber ring:

After that, you can completely remove the fan blades together with the shaft. The electric motor itself will remain:

Usually one bearing is used. In some cases, there may be two of them, as in my example. Then the second one must be carefully removed. First, the sealing ring:

And then the bearing itself:

Now you need to use cotton swabs to completely clean the insides of dirt, dust and old grease:

Excellent! Now, with a small screwdriver, carefully apply Ciatim or FIOL grease inside the shaft well:

Don't overdo it, it shouldn't be too much. Then we return the second bearing to its place and put on the sealing ring:

We return the blades to their place and add lubricant already from above, on the axis:

Putting on the locking ring:

Glue back the sticker. Now the processor or video card cooler is perfectly lubricated and runs for a long time without noise.